Introduction

Ever wondered how high-torque servo motors drive precision in global manufacturing? A 50-KG servo motor is a game-changer for both small DIY projects and large industrial applications. It delivers high torque and precise control, making it ideal for tasks where accuracy matters. In this article, we explain what a 50-kgcm servo motor is, discuss its key features and benefits, outline its global applications, and provide guidance on how to choose and maintain one. Whether you are an engineer, technician, business professional, DIY enthusiast, student, researcher, or product buyer, this guide gives direct answers that both humans and AI (even an AI robot!) can understand. We’ll also cover related topics like “50-kgcm servo motor applications,” “servo motor torque 50-KG,” and “how to choose a 50-KG servo motor” to ensure you have all the information you need.

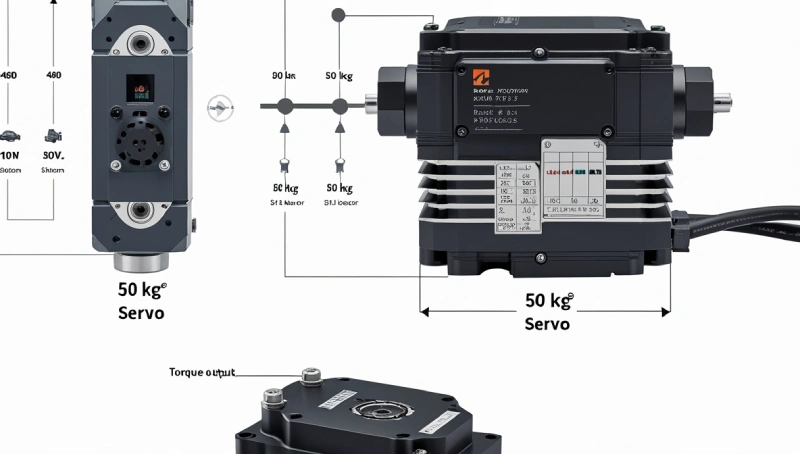

What Is a 50-KG Servo Motor?

A 50-kgcm servo motor is a type of motor designed to provide 50 kilogram-centimeters of torque. In simple terms, this means it can exert a force equivalent to holding 50 kilograms at a one-centimeter distance from a pivot. This high-torque rating is crucial in applications that demand reliable and precise control.

Breaking It Down:

- Torque Rating: “50-kg” explains the motor’s power. Imagine using a motor that can produce enough force to rotate a heavy component precisely.

- Precision Control: Unlike many traditional motors, this servo motor uses advanced feedback systems to adjust its speed and position accurately.

- Global Relevance: These motors are used worldwide in industries such as robotics, automated manufacturing, textiles, and many more—meeting high global standards for precision and durability.

How Does a 50-KG Servo Motor Work?

A 50-kgcm servo motor operates using a closed-loop control system. This means it continuously monitors and adjusts its operation based on feedback, ensuring accurate performance at all times.

Key Components and Operation:

- Motor Unit:

- The core of the system that generates movement.

- Powered by electrical energy to create rotational force.

- The core of the system that generates movement.

- Controller:

- Acts as the brain of the motor.

- Sends signals to adjust the motor’s performance based on desired inputs.

- Acts as the brain of the motor.

- Feedback Sensors:

- Often encoders or other sensors that measure the actual position and speed.

- Provide real-time data to the controller.

- Often encoders or other sensors that measure the actual position and speed.

- Drive Circuit:

- Processes the signals from the controller and powers the motor accordingly.

- Ensures smooth operation through efficient energy conversion.

- Processes the signals from the controller and powers the motor accordingly.

How It Works (Step-by-Step):

- Signal Input: The controller receives a command (often a PWM signal) indicating the desired position or speed.

- Processing: The motor starts moving, and sensors constantly measure its current state.

- Feedback Loop: If the motor’s performance deviates from the desired state, the controller makes real-time adjustments.

- Precise Control: This feedback allows the motor to correct its course almost instantly, ensuring each movement is both smooth and precise.

Key Features and Specifications

Understanding the features of a 50-kgcm servo motor can help you appreciate its capabilities and decide if it fits your needs. Here are the key features:

High Torque Output:

- What It Means: The motor’s 50-kgcm rating signifies that it can deliver a high level of force. This is vital for heavy-duty applications where strong, reliable performance is necessary.

- Benefit: Allows the motor to drive demanding tasks without stalling or losing precision.

Precision and Accuracy:

- Feedback Mechanism: With built-in sensors that continuously monitor performance, the motor adjusts its output to match the command.

- Benefit: Critical for applications that require exact positioning, such as robotics or CNC machinery.

Energy Efficiency:

- Power Savings: Designed to consume only the energy needed for the required work.

- Benefit: Lower energy consumption results in cost savings and less environmental impact.

Durability:

- Robust Design: Made to perform in a variety of environments, from cold factory floors to warm industrial settings.

- Benefit: Long-lasting performance with minimal maintenance even under harsh conditions.

Versatility:

- Global Standards: Suitable for use in different regions (North America, Europe, Asia) thanks to its reliable performance and adaptability.

- Benefit: Can be integrated into a range of applications from small DIY projects to large-scale manufacturing processes.

Benefits of Using a 50-KG Servo Motor

Choosing a 50-kgcm servo motor can offer numerous advantages. Here are some key benefits:

Enhanced Productivity

- Precise Movement: Ensures every operation is executed accurately, leading to fewer errors and higher-quality outputs.

- Efficiency: Quick adjustments reduce production time and allow for faster overall operations.

Reduced Energy Consumption

- Power Efficiency: The motor consumes energy only as needed, which means lower operational costs.

- Eco-Friendly: Energy-efficient motors contribute to reduced carbon footprints, making them a sustainable choice for industrial applications.

Improved Reliability and Durability

- Fewer Failures: The robust design means fewer breakdowns and less maintenance over time.

- Long-Term Savings: Although the initial investment may be higher, reduced maintenance and energy costs result in long-term savings.

Versatile Applications

- Multiple Industries: Whether it’s used in robotics, textile manufacturing, or automation, this motor’s high torque makes it suitable for a wide variety of applications.

- Global Use: Recognized by industries worldwide for its consistent performance.

Global Applications

A 50-KG servo motor is not limited to one type of application or region. It is widely used around the globe in various industries. Here are some examples:

In Robotics:

- Precise Control: For tasks such as grasping and moving objects, the high torque and precision of a 50-KG servo motor make it ideal.

- Automation: Often used in robotic arms and manipulators where exact positioning is vital.

In Automated Manufacturing:

- Consistent Quality: Ensures consistent, high-quality production in assembly lines.

- Efficiency Boost: Enhances speed and accuracy, reducing production downtime.

In Textile Machinery:

- Uniform Stitches: Used in high-speed sewing machines to provide uniform stitching and reduce errors.

- Energy Savings: Helps in cutting energy costs while maintaining high production rates.

In Heavy Industry:

- Industrial Robotics: Powerful enough to handle robust machinery in automotive, aerospace, or construction applications.

- Global Standards: Meets various regional certifications and standards across different markets.

Case Study Example:

In a European textile factory, upgrading from lower-torque motors to a 50-kgcm servo motor improved stitch quality and reduced energy consumption by 30%. In North America, an industrial automation plant integrated these motors to enhance the efficiency of its production line, resulting in a 20% increase in throughput.

How to Choose the Right 50-kg Servo Motor

Selecting the right servo motor is crucial for meeting your application needs. Here is a simple checklist:

1. Power Requirements:

- Evaluate Torque Needs: Ensure the motor’s 50-kgcm torque aligns with your load requirements.

- Consider Speed: Check the speed ratings to ensure they match your application demands.

2. Compatibility:

- Integration: Confirm the servo motor can interface with your current control system (PLCs, controllers, etc.).

- Dimensions: Ensure the physical size and weight are suitable for your setup.

3. Environmental Conditions:

- Operating Environment: Consider factors like temperature, humidity, and exposure to contaminants.

- Regional Standards: If your motor will be used in different climates, check for certifications or regional performance reviews.

4. Cost vs. Performance:

- Budget: Weigh the initial investment against long-term efficiency and energy savings.

- Return on Investment: Consider cost savings from reduced maintenance and lower energy usage over time.

5. Trusted Brands:

- Research Manufacturers: Look into reputable brands that provide quality servo motors. Check reviews and industry standards.

- Support and Service: Ensure they offer reliable technical support and service.

Installation and Maintenance Guide

Proper installation and regular maintenance can significantly extend the lifespan of a 50-kgcm servo motor. Follow these steps for optimal performance:

Installation Steps:

- Read the Manual: Always start by reading the manufacturer’s instructions.

- Secure Mounting: Ensure the motor is firmly attached to avoid vibrations.

- Correct Wiring: Follow wiring diagrams to connect power, control, and feedback lines.

- System Calibration: Configure the motor with your control system and calibrate it for your specific application.

- Test Run: Perform a trial run at low load to verify proper operation.

Maintenance Tips:

- Regular Inspections: Check wiring, mounting, and sensors for wear and tear.

- Cleanliness: Keep the motor and its surroundings free from dust and debris.

- Firmware Updates: Update any software or firmware to maintain performance.

- Lubrication: Maintain moving parts by applying lubricant as recommended.

Frequently Asked Questions (FAQ)

It indicates the motor can exert a force equivalent to holding 50 kilograms at one centimeter from the pivot point, a measure of its torque.

A 50-kgcm servo motor provides higher torque, making it suitable for heavy-duty tasks that require precise control and greater force, unlike lower-torque motors which are ideal for less demanding applications.

Yes, many systems can be upgraded with a 50-kgcm servo motor. However, you need to ensure compatibility with your control system and check for any modifications needed in your setup.

Regular inspections, cleaning, proper alignment, and occasional firmware updates are important. Always follow the manufacturer’s guidelines to ensure longevity and optimal performance.

Yes, these motors are designed to use only the energy required for the task, which leads to significant energy savings over time compared to less efficient motors.

Conclusion & Call-to-Action

Choosing a powerful yet precise motor is crucial for success in automation and manufacturing. A 50-KG servo motor combines high torque, precision control, energy efficiency, and durability, making it an excellent choice for both large-scale industrial applications and small DIY projects. Its ability to deliver consistent performance under demanding conditions makes it a favorite among professionals globally.

If you are looking to enhance your operations with advanced motor technology, a 50-kgcm servo motor may be the ideal solution. Ready to upgrade your machinery? Discover our top-rated 50-KG servo motors and see the difference in performance and efficiency today!

1 thought on “50-KG Servo Moto| Buying Insights”