Linear encoders are essential tools in precision engineering, manufacturing, and automation. Whether you’re a beginner exploring the world of motion control or a professional looking to upgrade your equipment, understanding linear encoders is crucial. In this guide, we’ll break down what linear encoders are, how they work, and how to choose the right one for your needs. We’ll also include product recommendations, a buying guide, and answers to common questions.

Amazon Newest Arrivals $123.00

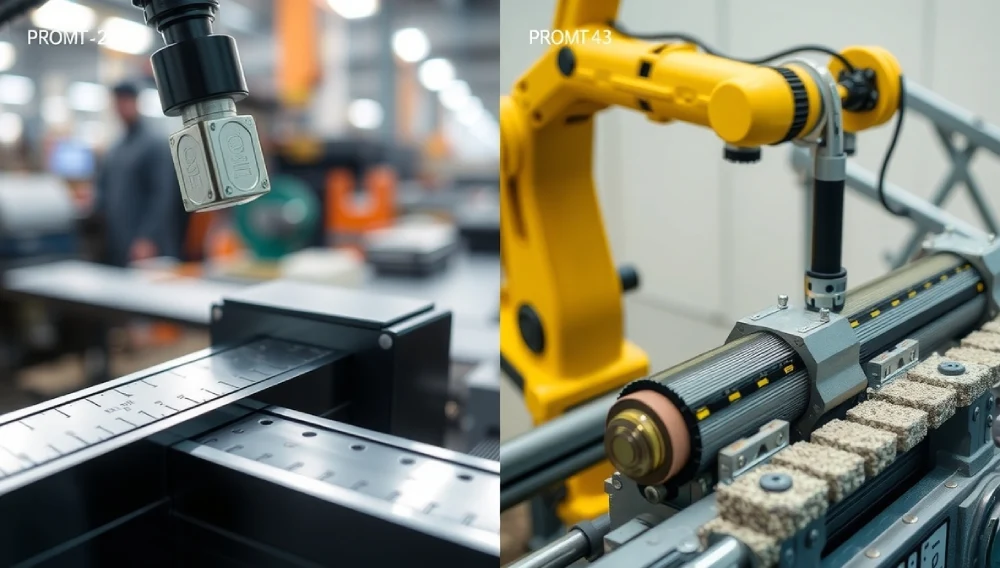

What is a Linear Encoder?

A linear encoder is a sensor or transducer that measures linear motion and converts it into digital or analog signals. It’s commonly used in applications requiring high precision, such as CNC machines, 3D printers, robotics, and medical devices.

How Does a Linear Encoder Work?

Linear encoders typically consist of two main components:

- Scale: A strip or rod with markings (optical, magnetic, or inductive).

- Read Head: A sensor that detects the markings and translates them into position data.

As the read head moves along the scale, it sends signals to a controller, which calculates the position, speed, and direction of the moving object.

Why Are Linear-Encoders Important?

Linear encoders play a critical role in ensuring accuracy and repeatability in various applications. Here’s why they matter:

- Precision: Provides accurate position feedback, often down to micrometers.

- Repeatability: Ensures consistent performance over time.

- Versatility: Works in harsh environments (e.g., high temperatures, dust, or vibrations).

- Automation: Enables precise control in automated systems.

Types

Linear encoders come in different types, each suited for specific applications:

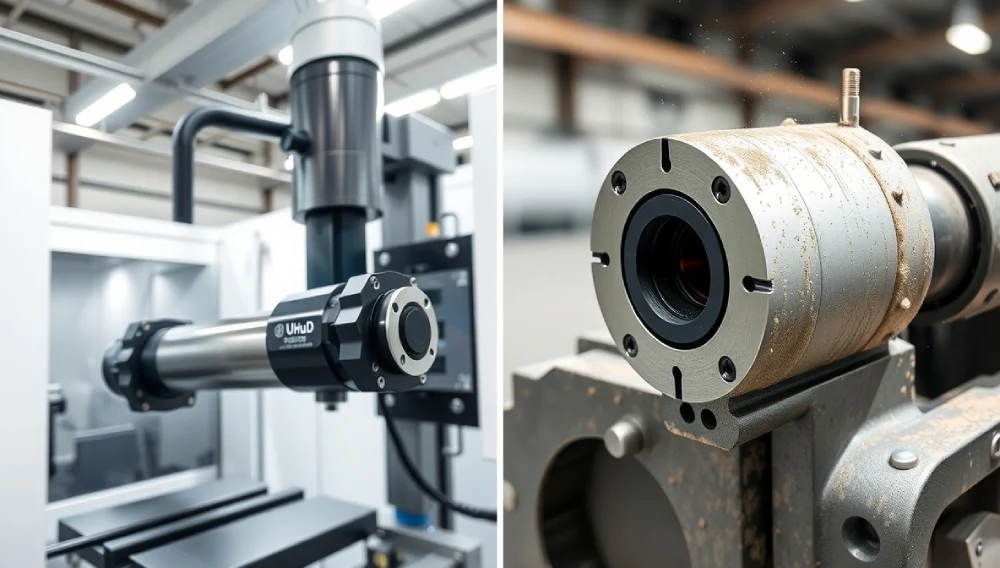

- Optical Linear-Encoders:

- Use light to detect position.

- High accuracy and resolution.

- Ideal for clean environments.

- Magnetic Linear-Encoders:

- Use magnetic fields to measure position.

- Durable and resistant to dust and moisture.

- Suitable for industrial environments.

- Inductive Linear-Encoders:

- Use electromagnetic induction.

- Robust and resistant to harsh conditions.

- Often used in heavy machinery.

Key Features to Look for in a Linear Encoder

When choosing a linear encoder, consider the following features:

- Resolution:

The smallest movement the encoder can detect (e.g., 1 micron). - Accuracy:

How closely does the encoder’s output match the actual position? - Speed:

The maximum speed at which the encoder can operate. - Durability:

Resistance to environmental factors like dust, moisture, and temperature. - Output Signal:

Analog (e.g., sine/cosine) or digital (e.g., TTL, SSI). - Mounting Options:

Compatibility with your system’s design. - Ease of Installation:

Plug-and-play setups save time and effort.

Top Product Recommendations

Here are some of the best linear encoders on the market:

1. Heidenhain LIDA 400 Series

- Pros:

- High accuracy (up to ±1 µm).

- Robust design for industrial use.

- Easy to integrate.

- Cons:

- Expensive.

- Requires professional installation.

Best for: High-precision industrial applications.

2. Renishaw RESOLUTE™ Absolute Optical Encoder

- Pros:

- Ultra-high resolution (up to 1 nm).

- Immune to dirt and contamination.

- Compact design.

- Cons:

- High cost.

- Limited to clean environments.

Best for: Advanced manufacturing and research.

3. RSF Elektronik MSK Series

- Pros:

- Affordable.

- High resolution and accuracy.

- Durable construction.

- Cons:

- Limited speed capabilities.

- Not ideal for harsh environments.

Best for: Small-scale CNC machines and 3D printers.

4. Balluff BML Magnetic Encoder

- Pros:

- Resistant to dust, moisture, and vibrations.

- Easy to install and maintain.

- Cost-effective.

- Cons:

- Lower resolution compared to optical encoders.

- Limited to industrial applications.

Best for: Heavy machinery and automation systems.

Linear Encoder Buying Guide

Choosing the right linear encoder can be overwhelming. Here’s a step-by-step guide to help you decide:

- Define Your Application:

Determine the level of precision, speed, and durability you need. - Check Compatibility:

Ensure the encoder works with your existing system. - Evaluate Environmental Conditions:

Choose an encoder that can withstand your operating environment (e.g., dust, moisture, temperature). - Set a Budget:

Linear encoders range from 100to100to10,000+. Decide how much you’re willing to spend. - Consider Installation and Maintenance:

Opt for encoders that are easy to install and maintain. - Read Reviews and Testimonials:

Learn from other users’ experiences to make an informed decision.

My Personal Experience

As someone who’s worked with CNC machines and robotics, I’ve used several linear encoders over the years. My go-to choice is the Heidenhain LIDA 400 Series for its unbeatable accuracy and reliability. However, for smaller projects, I’ve found the RSF Elektronik MSK Series to be a cost-effective and reliable option. If you’re working in harsh environments, the Balluff BML Magnetic Encoder is a solid choice.

FAQs

1. What’s the difference between linear and rotary encoders?

Linear encoders measure straight-line motion, while rotary encoders measure rotational motion.

2. Can I use a linear encoder in a dirty environment?

Yes, magnetic and inductive encoders are designed for harsh conditions.

3. How do I calibrate a linear encoder?

Calibration involves aligning the scale and read head, then verifying accuracy using a reference standard.

4. What’s the lifespan of a linear encoder?

With proper maintenance, linear encoders can last for years or even decades.

5. Do I need a controller for a linear encoder?

Yes, a controller processes the encoder’s signals and provides position feedback.

Final Thoughts

Linear encoders are indispensable tools for achieving precision and accuracy in modern engineering and manufacturing. Whether you’re working on a small DIY project or managing a large-scale industrial operation, there’s a linear encoder that fits your needs. By considering factors like resolution, durability, and compatibility, you can find the perfect encoder to enhance your system’s performance.

More Blog: HDMI streaming encoder

1 thought on “The Best Linear Encoders 2025”