Programmable Logic Controllers (PLCs) are the backbone of industrial automation, and allen bradley programmable logic controller is one of the most trusted brands in the industry. Whether you’re a beginner or a seasoned professional, understanding Allen Bradley PLCs can help you optimize automation processes efficiently.

In this guide, we’ll cover:

- What is an Allen Bradley PLC?

- Key features and benefits

- Top Allen Bradley PLC models (with pros & cons)

- Buying guide

- Personal experience & tips

- FAQs

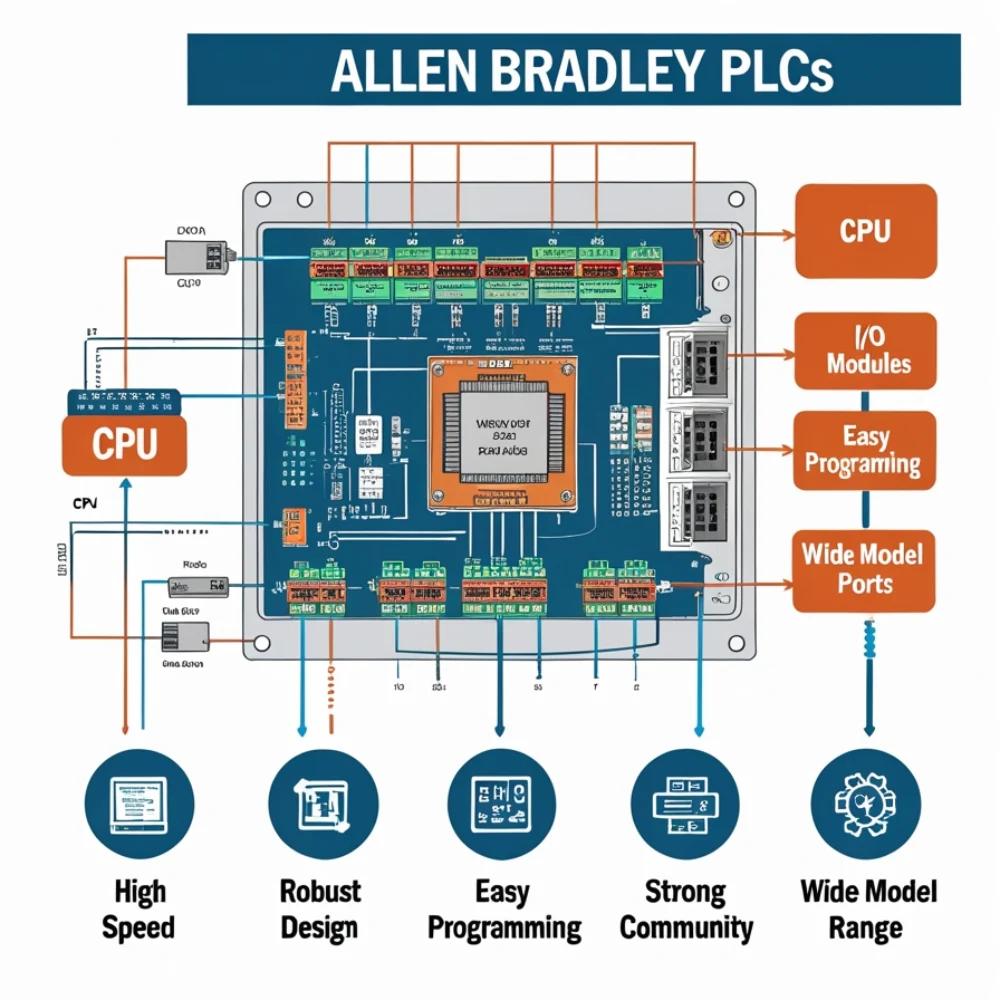

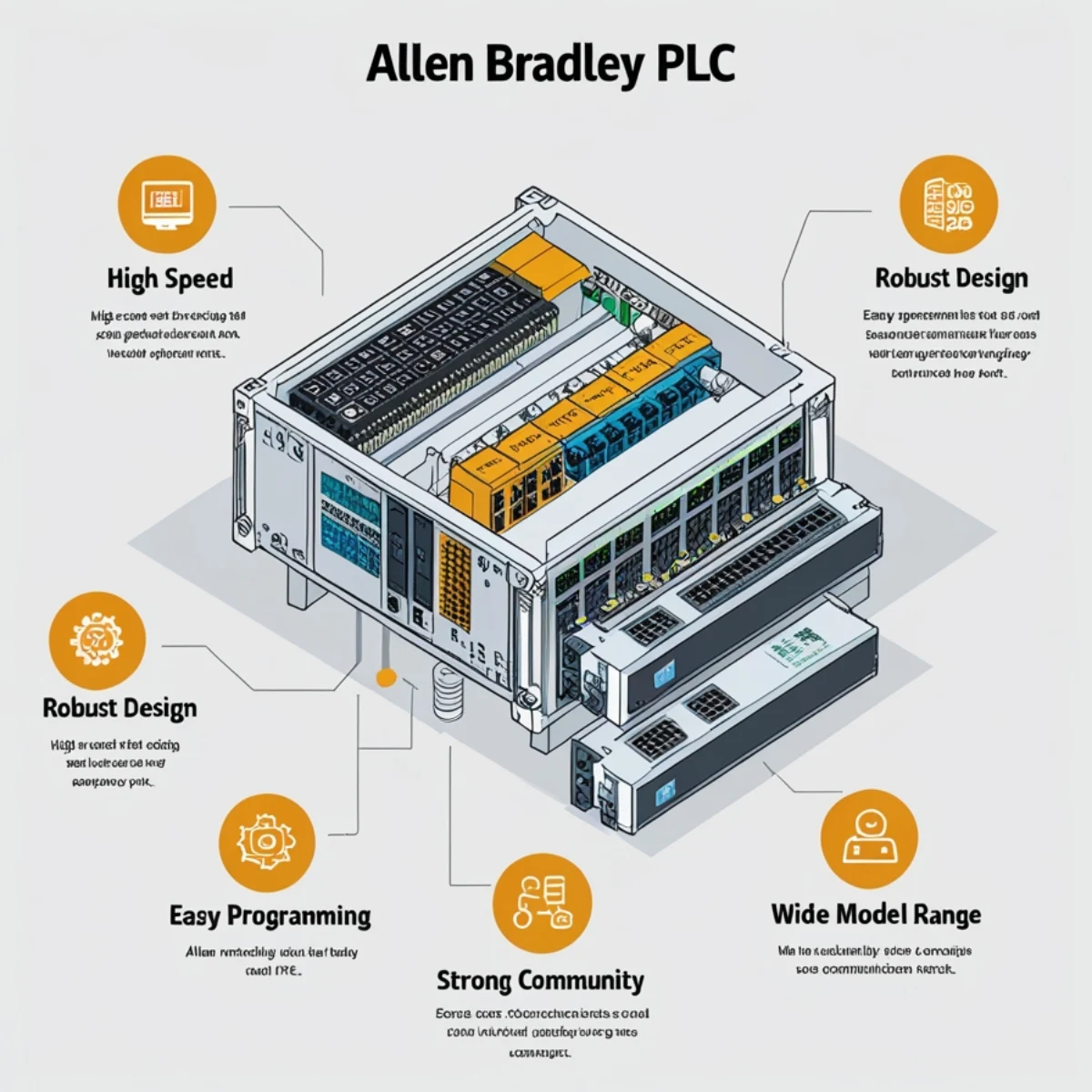

What is an Allen Bradley PLC?

An Allen Bradley PLC (by Rockwell Automation) is a rugged industrial computer designed to control manufacturing processes, machinery, and assembly lines. These PLCs are known for their:

- Reliability – Built for harsh industrial environments.

- Scalability – Suitable for small to large automation systems.

- User-friendly software – RSLogix and Studio 5000 make programming easy.

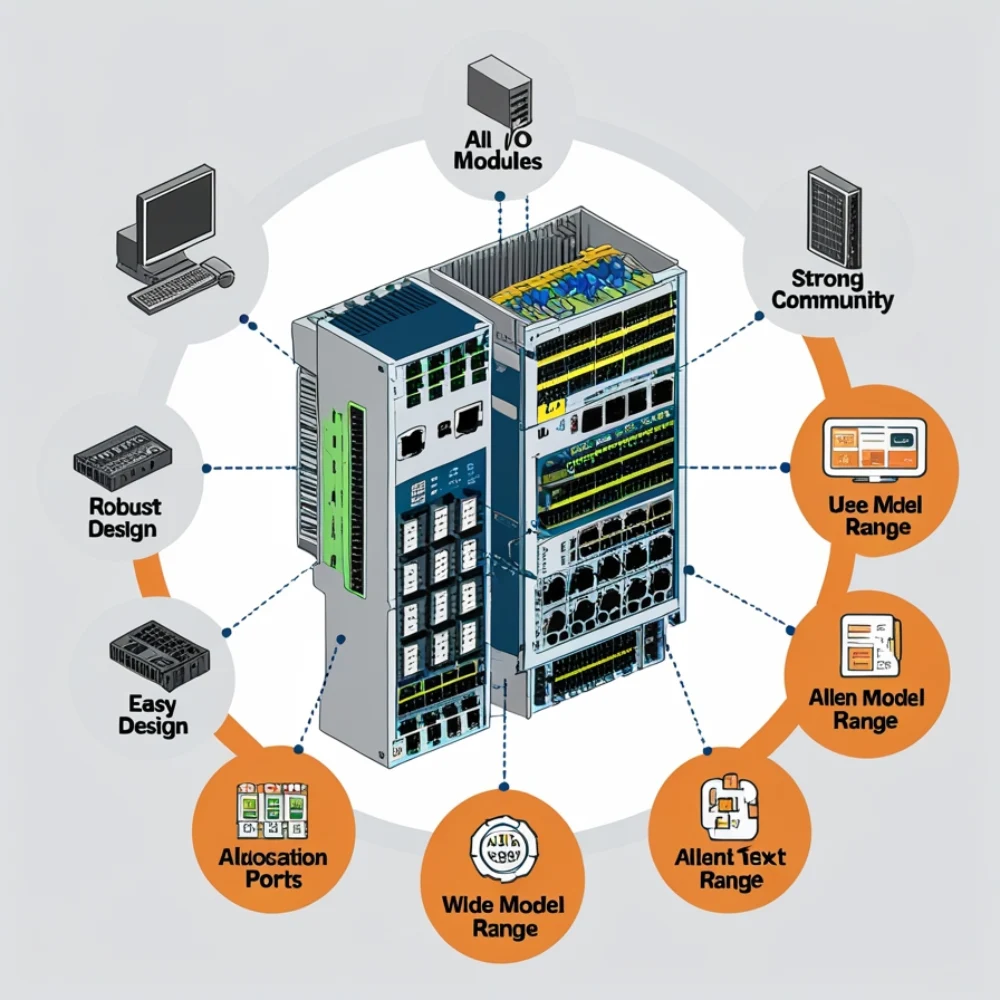

Key Features & Benefits of Allen Bradley PLCs

1. High Performance & Speed

- Fast processing for real-time control.

- Handles complex logic and multiple I/O modules.

2. Robust & Durable

- Operates in extreme temperatures and vibrations.

- Resistant to electrical noise.

3. Easy Programming & Integration

- Uses ladder logic, structured text, and function block diagrams.

- Compatible with Studio 5000 and RSLogix 5000.

4. Strong Support & Community

- Extensive documentation and training resources.

- Large user community for troubleshooting.

5. Wide Range of Models

From compact MicroLogix to high-end ControlLogix, there’s a PLC for every need.

Top Allen Bradley PLC Models (With Pros & Cons)

1. Allen Bradley MicroLogix 1100

✅ Pros:

- Affordable entry-level PLC.

- Built-in Ethernet for easy connectivity.

- Compact design for small applications.

❌ Cons:

- Limited memory and I/O capacity.

- Not ideal for complex automation.

Best for: Small machines, basic automation.

2. Allen Bradley CompactLogix 5370

✅ Pros:

- Modular design for scalability.

- Supports motion control and safety functions.

- Works with Studio 5000.

❌ Cons:

- Higher cost than MicroLogix.

- Requires more programming expertise.

Best for: Mid-range automation, packaging, and material handling.

3. Allen Bradley ControlLogix 5580

✅ Pros:

- High-speed processing for large-scale automation.

- Supports multiple communication protocols.

- Redundancy options for critical systems.

❌ Cons:

- Expensive.

- Complex setup for beginners.

Best for: Large factories, oil & gas, automotive plants.

Allen Bradley PLC Buying Guide

1. Determine Your Needs

- Small projects? → MicroLogix or CompactLogix.

- Large industrial systems? → ControlLogix.

2. Check I/O Requirements

- Count the number of inputs/outputs needed.

- Plan for future expansion.

3. Consider Communication Options

- Ethernet/IP, DeviceNet, or ControlNet?

- Ensure compatibility with existing systems.

4. Budget & Support

- Entry-level PLCs cost 500−500−2,000, while high-end models go up to $10,000+.

- Factor in software (Studio 5000 licenses can be expensive).

5. Where to Buy?

- Authorized distributors (like Rockwell Automation partners).

- Online marketplaces (Amazon, eBay – but beware of counterfeit products).

Personal Experience & Tips

I’ve worked with Allen Bradley PLCs for over 5 years, and here’s what I’ve learned:

✔ Start with MicroLogix if you’re new—it’s beginner-friendly.

✔ Use Studio 5000’s simulation mode to test logic before deployment.

✔ Backup your programs—PLC failures happen!

✔ Join forums like PLCTalk for troubleshooting help.

FAQs About Allen Bradley PLCs

1.RSLogix 500 (for MicroLogix/SLC 500).

2.Studio 5000 (for CompactLogix/ControlLogix).

Yes, using gateways or OPC servers, but direct compatibility is limited.

Typically 10-15 years, depending on maintenance.

Yes, but buy from trusted sellers and check warranties.

CompactLogix = Mid-range, cost-effective.

ControlLogix = High-end, for large-scale automation.

Final Thoughts

Allen Bradley programmable logic controller are industry leaders for a reason—they’re reliable, scalable, and packed with features. Whether you’re automating a small machine or a full production line, there’s an Allen Bradley PLC that fits your needs.

Need help choosing? Drop a comment below!

Read More: programmable logic controller arduino

Read More: Allen Bradley (Human Machine Interface)

2 thoughts on “Allen Bradley PLC |Rates | Tips | Maintenance | FAQ |”