Introduction

Picture a robotic arm in a science fair project waving hello, a drone adjusting its camera angle mid-flight, or a smart plant-watering system turning its nozzle with perfect accuracy. These feats are powered by tiny servo motors—compact, smart engines that make precision possible in the smallest spaces. Whether you’re a student building your first robot, an engineer designing medical devices, or a hobbyist crafting DIY gadgets, tiny servo motors are your go-to for controlled movement.

By the end of this guide, you’ll know:

- What makes tiny servo motors unique (spoiler: they’re like pocket-sized robots).

- How they work, their top uses, and how to pick the right one.

- Pro tips for installation, maintenance, and avoiding common mistakes.

Let’s dive in!

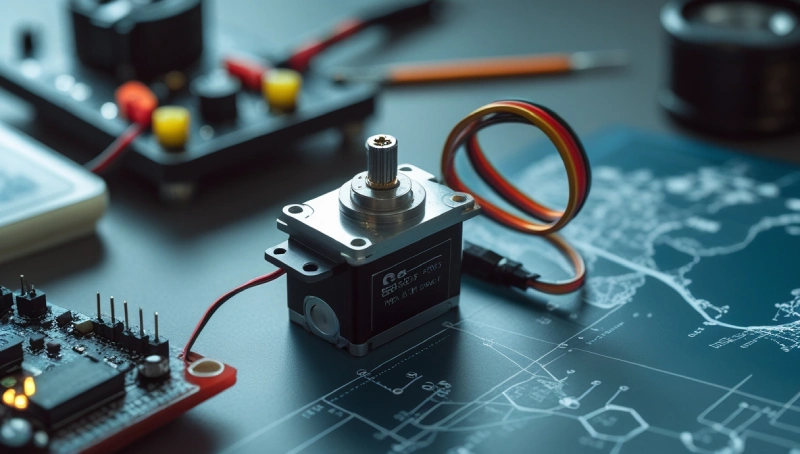

What is a Tiny Servo Motor?

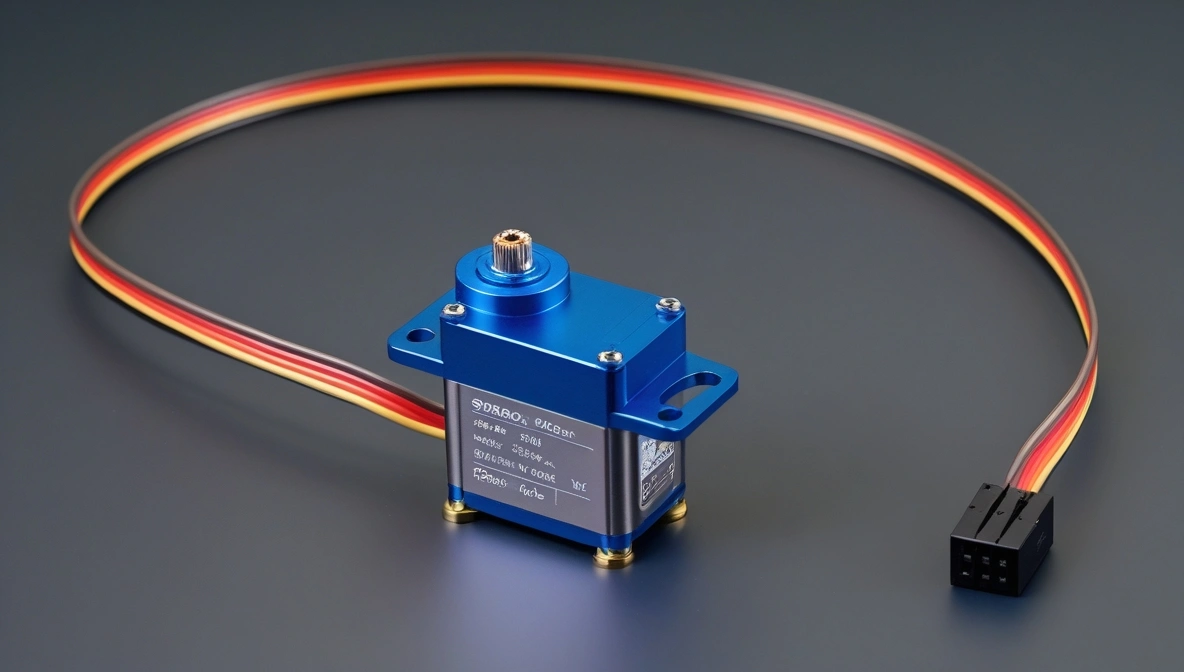

A tiny servo motor is a miniature version of a standard servo motor, designed to deliver precise control over position, speed, or torque in ultra-compact devices. Think of it as a microscopic traffic cop—directing motion with pinpoint accuracy, even in tight spaces like camera gimbals or robotic fingers.

Key Features:

- Size: As small as a thumb (e.g., 12mm x 30mm).

- Weight: Light as a feather (some weigh just 5 grams!).

- Control: Operates via PWM signals (like secret codes from Arduino).

Real-World Analogy:

It’s like the steering wheel of a toy car—small but mighty, guiding every turn with precision.

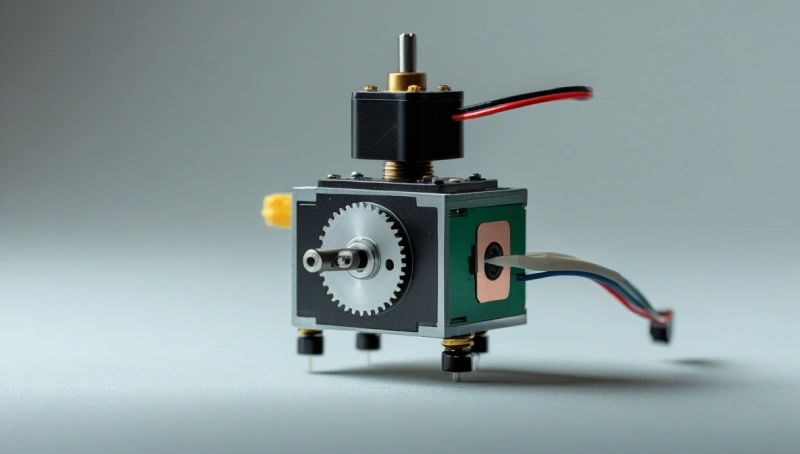

How Does a Tiny Servo Motor Work?

Here’s the step-by-step magic:

- Command: You send a signal (e.g., “Turn 45 degrees”).

- Movement: The motor’s gears start spinning.

- Feedback: A potentiometer tracks the angle.

- Adjustment: The control circuit tweaks power until the target is hit.

Key Components:

- Motor: Tiny but powerful (often DC or coreless).

- Gears: Nylon or metal (for durability).

- Potentiometer: Acts as the motor’s “eyes.”

- Control Board: The brain processing commands.

Key Features and Specifications

| Feature | Why It Matters |

| Ultra-Compact | Fits drones, wearables, and micro robots. |

| Precision | Accuracy up to ±0.5° (perfect for cameras). |

| Low Power | Runs for hours on coin-cell batteries. |

| Speed | 0.12 seconds/60° (faster than a hummingbird’s wing!). |

Why Choose a Tiny Servo Motor?

- Space-Saving: Perfect for projects where every millimeter counts.

- Energy Efficiency: Sips power, ideal for portable gadgets.

- Affordability: Starts at $3 (e.g., SG90).

- Plug-and-Play: Works seamlessly with Arduino and Raspberry Pi.

Tiny vs. Small Servo Motors:

| Feature | Tiny Servo Motor | Small Servo Motor |

| Size | 12mm-20mm | 25mm-35mm |

| Torque | 1.2-2.5 kg/cm | 3-6 kg/cm |

| Best For | Micro robots, DIY toys | RC cars, small robotic arms |

Where Are Tiny Servo Motors Used?

Global Applications:

| Region | Industry | Example |

| Japan | Robotics | Robotic hands in miniature factory models. |

| USA | Drones | Adjusting camera angles in hobby drones. |

| Germany | Medical Devices | Precision tools for minimally invasive surgery. |

| India | Education | STEM kits for school robotics competitions. |

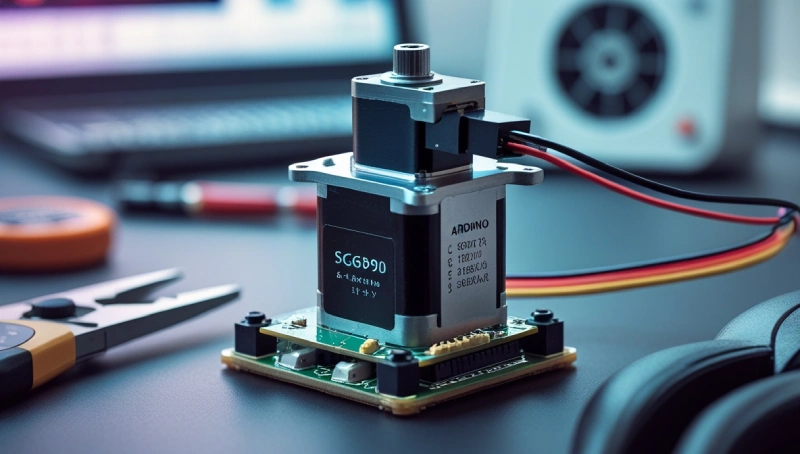

How to Choose the Right Tiny Servo Motor

5-Step Checklist:

- Purpose:

- Precision tasks (e.g., camera focus): Metal gears.

- Lightweight projects (e.g., paper robots): Nylon gears.

- Voltage:

- 3.7V-6V (match your battery or microcontroller).

- Size:

- Measure your project’s space (e.g., 9g servos for micro drones).

- Torque:

- 1.5 kg/cm for most tiny tasks.

- Budget:

- 3−

- 3−15 (MG90S, TowerPro SG92R).

Pro Tip: For Arduino projects, check PWM compatibility!

FAQs: Your Questions Answered

No—they’re built for precision, not heavy lifting. Opt for gearmotors for weights above 50g.

Most aren’t, but waterproof models like Power HD WP-23A exist for outdoor projects.

30,000-50,000 cycles with proper care—about 2-3 years of heavy use.

Yes! Use a servo driver board (e.g., PCA9685) to control up to 16 motors.

Conclusion: Think Small, Build Big!

Tiny servo motors prove that size doesn’t limit innovation. From Japanese micro-factories to Indian classroom robots, these motors are the secret sauce behind precision in small-scale tech.

Ready to Start?

- Grab budget models on Amazon or premium picks on SparkFun.

- Check Out our 50-kgcm Servo Motor Review! .

About the Author:

John Carter is a robotics educator who’s built award-winning micro robots. She’s passionate about making tech accessible to everyone, from kids to CEOs.

1 thought on “Tiny Servo Motors: The Mighty Mini Engines Powering Precision”