Introduction

Ever wondered how massive industrial machines or factory equipment starts up smoothly without burning out? The secret lies in 3 phase motor starters—devices that safely power up heavy-duty motors. Whether you’re an engineer designing a production line or a DIYer working on a workshop project, this guide will explain 3 phase motor starters in plain language, compare popular types like Square D motor starters, and even help you pick the right one. Let’s dive in!

What Is a 3 Phase Motor Starter?

A 3 phase motor starter is an electrical device that safely starts, stops, and protects three-phase motors (common in industrial settings). It prevents power surges, overheating, and electrical fires by controlling how the motor receives energy. Think of it as a motor’s “bodyguard”!

Key Jobs of a Motor Starter:

- Smooth Start: Reduces initial power surge by 50–70%.

- Overload Protection: Shuts off the motor if it’s overworked.

- Control: Lets you start/stop the motor remotely or automatically.

How Does a Three Phase Motor Starter Work?

Let’s break it down like a recipe:

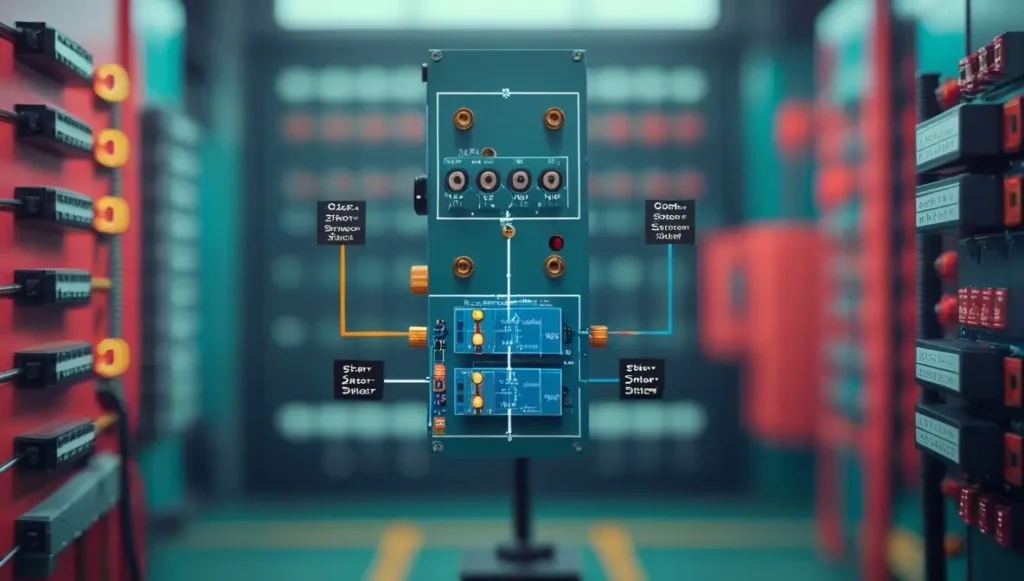

- Power Up: You press the start button, sending electricity to the starter.

- Contactor Closes: Electromagnets pull metal contacts together, letting power flow to the motor.

- Motor Runs: The motor spins up gradually (or at full speed, depending on the starter type).

- Safety Net: If the motor overheats, a thermal relay cuts the power.

Why It’s Important:

Without a starter, a 3-phase motor can draw up to 6x its normal current at startup, risking burnout or tripped circuits!

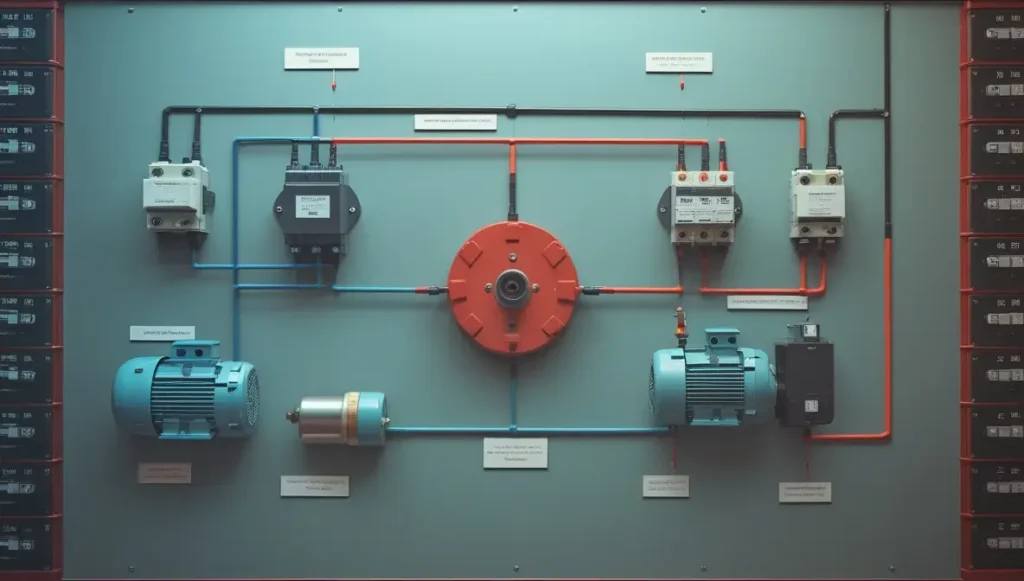

Three-phase motor starters are built for handling the high power needs of industrial motors. Unlike single-phase systems, three-phase starters manage the balanced power from three supply lines, providing efficient and reliable starts. Common types include Direct-On-Line (DOL) starters, which apply full voltage immediately, and Star-Delta starters, which reduce starting voltage to limit current surge. DOL starters are simple and cheap, but cause large inrush currents. Star-delta (or autotransformer) starters begin with reduced voltage for a gentler start, then switch to full power once running. Knowing your motor’s load and power requirements helps determine the ideal starter type.

Types of Three Phase Motor Starters

Not all starters work the same. Here’s a quick cheat sheet:

| Type | How It Works | Best For |

| DOL (Direct-On-Line) | Full power at startup. Simple, cheap. | Small motors (e.g., pumps, fans). |

| Star-Delta | Starts in low-power “star” mode, switches to “delta” for full speed. | Medium motors (e.g., compressors). |

| Soft Starter | Gradually increases voltage. Smooth start. | Conveyor belts, crushers. |

| VFD (Variable Frequency Drive) | Controls speed and startup. | Precision tasks (e.g., CNC machines). |

Pro Tip: For heavy machinery, Square D motor starters from Schneider Electric are known for durability and easy maintenance.

How to Choose the Right Starter

Picking the perfect starter depends on:

- Motor Size: Match the starter’s current rating (e.g., 10A, 20A) to your motor.

- Application:

- Soft Starters for elevators or conveyor belts.

- VFDs for tasks needing speed adjustments.

- Budget:

- DOL starters:

- 50–

- 50–200.

- VFDs:

- 300–

- 300–2,000+.

- Brand Trust: Brands like Square D, Siemens, and ABB lead in reliability.

DIY Example: A hobbyist building a woodshop lathe might opt for a Square D NEMA-rated DOL starter for its plug-and-play design.

Wiring a 3 Phase Motor Starter: Basics

Here’s a simplified setup for a DOL starter:

- Turn Off Power: Safety first—use a voltage tester!

- Connect Power Wires: Link L1, L2, L3 (phases) to the starter.

- Wire Control Circuit: Add start/stop buttons and a thermal relay.

- Test: Power on and press the start button.

Where Are 3 Phase Motor Starters Used?

You’ll find them in almost every industry:

- Factories: Conveyor systems, industrial fans.

- Construction: Cranes, cement mixers.

- Agriculture: Irrigation pumps, grain elevators.

- Home Workshops: Large saws, CNC routers.

Real-World Example:

A brewery might use a soft starter to power a massive bottling machine without jolting the electrical system.

Top 3 Phase Motor Starter Brands

- Square D (Schneider Electric):

- Model: Square D Type S.

- Pros: Durable, easy to install.

- Siemens:

- Model: Sirius 3RW5.

- Pros: Advanced diagnostics.

- ABB:

- Model: ABB ACS880.

- Pros: Energy-efficient VFDs.

Where to Buy: Amazon, Grainger, or directly from brand websites.

Pros and Cons

Pros

✅ Prevents motor burnout and electrical fires.

✅ Extends motor lifespan.

✅ Simple models (like DOL) are DIY-friendly.

Cons

❌ High-end VFDs require expert programming.

❌ Industrial starters can be bulky.

FAQs

Yes, but check the starter’s current rating matches the motor.

Starters control startup; breakers only stop overloads.

Yes—they protect the motor and power supply.

Turn off power, let the motor cool, then press the reset button.

Yes—they’re more durable and comply with strict safety s

A star-delta starter first connects the motor windings in a star (Y) configuration to start with lower voltage and current, then switches to a delta (Δ) for normal running. This reduces mechanical and electrical stress during startup. It’s ideal for large motors (e.g., pumps, compressors) that require a softer start to avoid high inrush currents.

Understanding starter and contactor combinations. Check here!

3 thoughts on “Three-Phase Motor Starters| Types| Applications & Selection Guide”