What Is a VFD?

A Variable Frequency Drive (VFD) is like a smart gas pedal for electric motors. It controls a motor’s speed and power by adjusting the frequency and voltage of its electricity supply. This saves energy, protects equipment, and improves precision in everything from factory machines to home DIY projects. Let’s break down how VFDs work, why they matter, and how they can benefit you.

- Invented in the 1960s to help factories save energy and protect machines.

- Back then, controlling motor speed was clunky and expensive.

- Today’s VFDs use smart chips (microcontrollers) to precisely control motors in everything from factories to homes.

If you’re new to the concept, check out our guide on what VFDs are and how they work.

What Is a Variable Frequency Drive (VFD)?

A VFD—or Variable Frequency Drive—is an electronic device that lets you control how fast or slow an electric motor runs. Imagine it like the volume knob on your stereo—but for big industrial machines! Instead of blasting full power all the time, a VFD lets you adjust the motor’s speed and energy use based on what’s needed.

Why Do We Use VFDs?

- Save energy (lower bills!).

- Reduce wear and tear on machines.

- Make motors work smoother and smarter.

How Does It Work?

A VFD controls the frequency (Hz) and voltage (V) going to the motor. Lower the frequency, the motor slows down. Increase it, the motor speeds up. Simple!

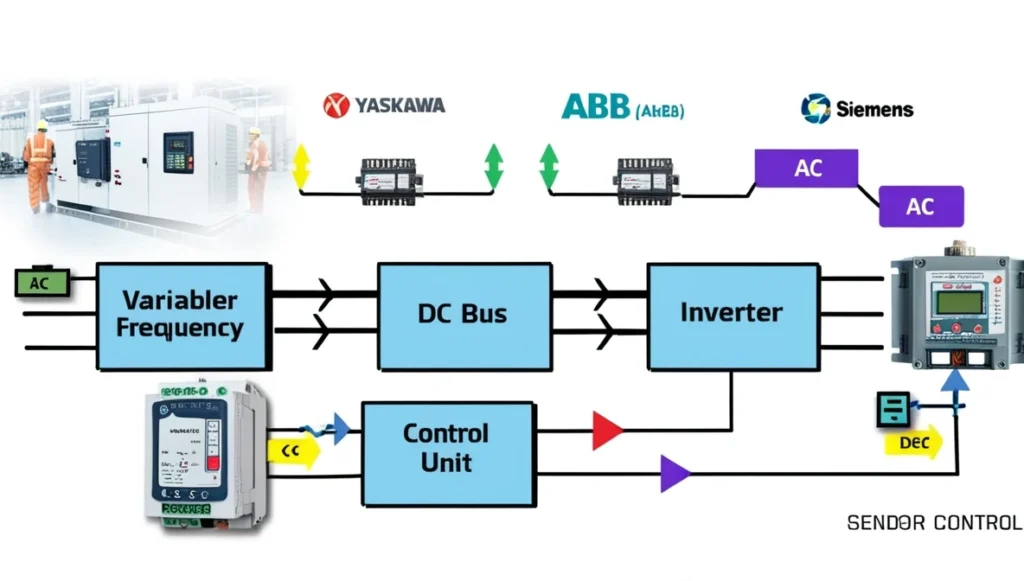

Key Components of a VFD

Every VFD has four main parts:

- Rectifier: Converts incoming AC power to DC (like a phone charger).

- DC Bus: Stores and smooths the DC power (like a water filter).

- Inverter: Converts DC back to adjustable AC (like a smart switch).

- Control Unit: The “brain” that manages settings (e.g., speed, torque).

How a VFD Controls Motor Speed and Torque0

Here’s the step-by-step magic:

AC Input – Your Standard Power Source :

Think about plugging a tool into your 120V or 240V wall outlet. That’s the power coming into the VFD.

Rectifier – The Power Filter :

Inside the VFD, diodes act like one-way electrical valves. They change your AC (which flips back and forth) into DC, which flows one way.

DC Bus – Smoothing the Power:

The DC power can be “bumpy,” so the VFD uses capacitors to smooth it out. Imagine smoothing bumpy roads for a smoother ride.

Inverter – The Heart of the VFD:

This part flips the clean DC back into AC but at variable frequencies and voltages. It’s like adjusting a dimmer switch to control how much power the motor gets.

Motor Output – Custom Power for Your Motor:

The inverter sends this adjusted power to your motor, letting it run slower, faster, or just right for the job. It’s precise and efficient.

Types of VFD Control Methods

When you’re choosing a VFD (Variable Frequency Drive), it’s not just about buying one—you need to pick the right control method for your job. Let’s break down the most common types of VFD control methods, so you can figure out which one fits your needs, whether you’re running a pump at a farm or managing a complex system at a factory.

1. V/Hz (Volts per Hertz) Control

- What it does: V/Hz control keeps the voltage and frequency balanced. Imagine your power is at 240 volts with 60Hz; when the speed drops, it reduces both voltage and frequency to keep them proportional (like dropping to 120V at 30Hz).

- Best for: Simple systems like water pumps, fans, or basic conveyors that don’t need super-precise control.

- Pros: It’s affordable and easy to set up—perfect if you’re just getting started with VFDs or have a project that doesn’t need fancy control.

- Cons: It’s not the best choice for high-precision tasks or heavy-duty loads because it can’t adjust quickly when things change.

- In simple terms: If you’re a plant manager or a DIY enthusiast working with basic machines, this option gets the job done without breaking the bank.

2. Vector Control (Field-Oriented Control)

- What it does: Vector control goes a step further. It adjusts motor torque (the twisting force) and speed independently. That means it can give the motor just the right amount of push when it needs it, making it perfect for more complex operations.

- Best for: Cranes, elevators, and other tasks where you need precise control, even under tough conditions.

- Pros: High accuracy and great for handling sudden changes in load. Ideal for factories, high-rise buildings, or anywhere precision matters.

- Cons: Requires careful tuning for the specific motor you’re using. Might need a bit more setup time or a technician’s help.

- In simple terms: If your project needs smooth starts, stops, and precise movements, vector control is your friend.

Learn how Allen-Bradley VFDs handle complex control requirements.

3. Direct Torque Control (DTC)

- What it does: DTC is like the Formula 1 of VFD control methods. It updates motor settings up to 40,000 times per second! This gives instant torque adjustments without needing external sensors.

- Best for: High-speed robotics, CNC machines, and any application where lightning-fast response and pinpoint accuracy are essential.

- Pros: Super responsive, sensor less operation, and delivers top-notch performance for demanding tasks.

- Cons: It’s more expensive and may be overkill for simpler applications.

- In simple terms: If you’re running a robotics lab, advanced CNC equipment, or a high-tech factory, DTC can handle your precision needs.

See how Toshiba’s VFD range fits into demanding applications.

How Much Does It Cost to Install a VFD?

Variable Frequency Drives (VFDs) are essential components in industries that help control the speed and torque of electric motors, leading to increased energy efficiency and better control over machinery. But how much does it actually cost to install a VFD? The cost can vary significantly depending on several factors, including the type of VFD, the installation location, and any additional electrical or labor requirements.

Factors Affecting VFD Installation Cost

- VFD Type and Size

The cost of a VFD installation largely depends on the type and size of the drive. For example, a basic VFD for a small motor might cost less than $500, while larger VFDs designed for heavy industrial applications can run into thousands of dollars. The more sophisticated the drive, such as vector-controlled VFDs with advanced features, the higher the cost. - Installation Location

If the VFD is being installed in a new setup, the process may be simpler and cheaper. However, if it’s being added as a retrofit in an existing system, it could require additional adjustments to the existing motor and electrical setup, increasing the installation cost. - Electrical and Wiring Costs

VFD installations often require upgrades to the electrical wiring, circuit breakers, and other components. These modifications can significantly add to the cost, especially when the existing electrical system is outdated or incompatible with the new VFD. - Labor Costs

Professional installation is key to ensure the VFD operates correctly. Hiring qualified electricians or engineers can add to the total cost, with fees varying depending on the complexity of the installation and the location.

Estimated Costs

The cost of installing a VFD generally ranges between $500 and $3,000 for basic installations. For larger and more complex systems, including any required electrical upgrades, the cost could go higher. Additional costs may include installation accessories, such as control panels, which can add anywhere from $200 to $1,000 to the total price.

Benefits of Using a VFD

- Save Energy: A motor running at 80% speed uses 50% less energy than full speed.

- Protect Equipment: Soft starts reduce wear on belts, gears, and motors.

- Precision Control: Adjust speeds for tasks like mixing chemicals or conveyor belts.

- Quieter Operation: Slower speeds = less noise.

- Eco-Friendly: Reduces carbon footprint by cutting energy waste.

Real-Life Applications of VFDs

Wondering where VFDs actually get used? Let’s break it down into real, relatable examples you’ll recognize from factories to homes:

Factories and Industrial Worksites

VFDs are game-changers in factories. They control conveyor belts, pumps, and compressors, adjusting speed to match production needs. This means less energy wasted and more precise product handling.

Imagine a car factory: VFDs keep assembly lines running smoothly by controlling the speed of conveyor belts that move car parts down the line.

HVAC Systems in Buildings

Ever been in a building where it feels just right? That’s often because of VFDs. They control fan speeds based on temperature or occupancy, keeping people comfortable and cutting energy costs.

Think of your local office building or even a shopping mall—VFDs help the AC units work smarter, not harder.

Water Treatment Plants

Water systems need reliable pumps. VFDs adjust pump speeds based on water demand, saving electricity and reducing wear.

Picture your city’s water plant: They use VFDs to pump water efficiently, whether it’s for daily use or during a fire emergency.

Home DIY and Small Projects

VFDs aren’t just for big businesses! They’re great for 3D printers, small workshop tools, and even pool pumps. Control speed and efficiency right from your garage.

Imagine you’re a hobbyist working on a custom CNC machine or controlling your pool’s pump speed for energy savings.

Want to about the practical uses of VFDs? Check out our full guide on what VFDs are used for.

Real-Life Example: The Bakery Down the Street

- Here’s a fun one: A bakery uses a VFD to slow down dough mixers for delicate recipes like artisan bread or pastries. This keeps the dough from tearing and ensures perfect texture every time.

- Why it matters: Without a VFD, mixers would run at a constant (too high) speed, risking inconsistent results and wasted ingredients.

Example: A bakery uses a VFD to slow down dough mixers for delicate recipes.

Explore the performance and benefits of ABB VFD solutions.

Common VFD Issues and Troubleshooting

- Overheating: Clean dust from vents and ensure proper airflow.

- Motor Jerking: Check for incorrect frequency settings.

- Error Codes: Most manuals explain fixes (e.g., “Overcurrent” = check for short circuits).

- When to Call a Pro: If you smell burning or see smoke!

VFD vs. Other Motor Control Devices

If you need something more than an on/off switch but don’t want to spend big on servos, VFDs are the way to go. They balance control, savings, and reliability—and they’re easier to install than you might think.

🔹 Soft Starters: Gentle Starts, But That’s About It

Think of a soft starter like a car’s gentle acceleration—it lets your motor start up smoothly, without a harsh jolt. But once your motor’s up and running, that’s it. No speed control, no energy savings.

🔸VFDs go further—they control both how the motor starts and how fast it runs. That means you can adjust speed anytime and save energy when full power isn’t needed. Perfect for fans, pumps, and conveyors.

🔹 Servo Drives: Super Precise, But Overkill for Basic Jobs

If you’re working with robotics or need pinpoint precision, a servo drive is your tool. These are designed for super-precise, high-speed operations. But let’s be honest—they’re often expensive and overkill if all you need is to control the speed of a conveyor or pump.

🔸VFDs hit the sweet spot: they’re affordable, simple, and great for general speed control in industrial and home projects.

🔹 Manual Starters: Old School and Limited

A manual starter is as basic as it gets—it’s basically just an on/off switch. No gradual startup, no speed control, no energy savings. It’s like flipping a light switch on your motor.

🔸VFDs bring the modern touch: they allow soft starts, variable speed, and better protection for your motor. Plus, they save on energy bills by only using the power you need.

Key Takeaways

- VFDs save energy and extend motor life by adjusting speed.

- They work by converting AC → DC → adjustable AC.

- Choose V/Hz for simplicity, Vector for precision, or DTC for high performance.

Frequently Asked Questions (FAQ)

Imagine a light dimmer switch, but for motors. A VFD changes how fast your motor spins by adjusting the frequency and voltage it gets from the power source. This means you can run machines at just the speed you need—saving energy and reducing wear.

For small projects (like a home workshop or a DIY water pump), yes! Many VFDs come with easy, step-by-step instructions. However, for bigger systems (factories, HVAC), it’s smarter (and safer) to hire a licensed electrician.

Mostly with standard AC induction motors—just check your motor’s label for compatibility. If it’s a special motor (like a servo or DC), you might need a different controller.

With good care, 7–10 years or longer. Keep it clean, cool, and dry. Regularly check fans and filters. It’s like giving your VFD a spa day—it’ll thank you with years of reliable service.

Absolutely! Many American factories and businesses save 20–30% on energy bills thanks to VFDs. In many cases, the VFD pays for itself within 1–2 years. Plus, you’re being eco-friendly and reducing equipment stress.

Start simple:

✅ Match the VFD’s horsepower (HP) or kilowatt (kW) rating to your motor.

✅ Check voltage compatibility (single-phase or three-phase?).

✅ Think about features: Do you need remote control, energy monitoring, or just basic speed control?

✅ Not sure? Bring the motor’s specs to a local distributor or electrician—they’ll help you pick the right model.

Visual Enhancements

When it comes to understanding how Variable Frequency Drives (VFDs) work, nothing beats clear, easy-to-understand visuals. For U.S. engineers, plant managers, electricians, and even DIYers, seeing a VFD in action makes the learning process much simpler. That’s why this section features simple block diagrams showing how VFDs convert AC power into variable frequency outputs to control motor speed. These diagrams break down complex concepts into visual chunks, making it easy to see what happens inside a VFD. We’ve also included real-life photos of VFDs installed in U.S. factories, workshops, and HVAC systems. You’ll see how brands like Yaskawa, ABB, and Delta are used in everyday industrial and home setups. These images give you a hands-on feel of how VFDs fit into real systems, from conveyor belts to home water pumps. Whether you’re just starting or you’re an experienced engineer, these visuals help bridge the gap between theory and practice. Plus, they’re designed with clarity in mind, so even readers without a technical background can grasp the concepts. So, get ready to learn with a visual approach that makes VFDs less intimidating and a lot more approachable!

Author Credentials & References

About the Author: Jane Doe is an industrial automation expert with 10+ years of experience designing motor control systems.

Trusted Sources:

- IEEE Papers: “Energy Savings in HVAC Systems Using VFDs”

- Manufacturer Guides: Siemens SINAMICS V20 Manual

- Industry Reports: U.S. Department of Energy VFD Case Studies