The Hidden Heroes Behind Modern Automation

Imagine a robotic arm at a BMW factory in Germany welding car frames with laser precision. Or a CNC machine in Tokyo cutting smartphone parts thinner than a strand of hair. These aren’t sci-fi scenes—they’re everyday miracles made possible by AC servo motors.

Whether you’re an engineer fine-tuning machines in Mumbai, a student building a DIY robot in Berlin, or a factory owner in Texas looking to upgrade, AC servo motors are the silent powerhouses behind speed, accuracy, and reliability.

In this guide, we’ll cover:

- Why AC servo motors beat DC motors in industrial setups

- How they power industries worldwide

- How to pick the right one for your local needs

- Installation, maintenance, and expert tips

What is an AC Servo Motor?

In simple terms, an AC servo motor is a smart, high-performance electric motor that runs on alternating current and precisely controls speed, torque, and position. Think of it like a Tesla’s autopilot system, but for factory machines—constantly adjusting in real-time to stay accurate and efficient.

Key Features:

- Closed-Loop Control: Uses encoders to automatically correct motion errors

- High Torque Output: Handles heavy-duty tasks without stalling

- Global Compatibility: Works on 110V (US), 220V (Europe/Asia), and 240V (Australia)

AC vs. DC Servo Motors ,What’s the Difference?

| Feature | AC Servo Motor | DC Servo Motor |

| Power Source | Alternating Current (AC) | Direct Current (DC) |

| Best For | Industrial-grade machines (CNC, robotics) | Hobby projects (Arduino, RC cars) |

| Lifespan | Longer (more durable, heat-resistant) | Shorter (more wear and tear) |

| Price | Higher upfront, lower maintenance cost | Cheaper but less efficient |

➡️ AC motors dominate industries like automotive, aerospace, and electronics due to their durability and precision.

How Do AC Servo Motors Actually Work?

Here’s the magic behind their precision:

- Command: The controller sends a target (e.g., “Move to 45° at 2,000 RPM”).

- Action: The stator’s magnetic field spins the rotor.

- Feedback: Encoders track position/speed 1,000 times per second.

- Adjustment: The controller tweaks voltage to stay on target.

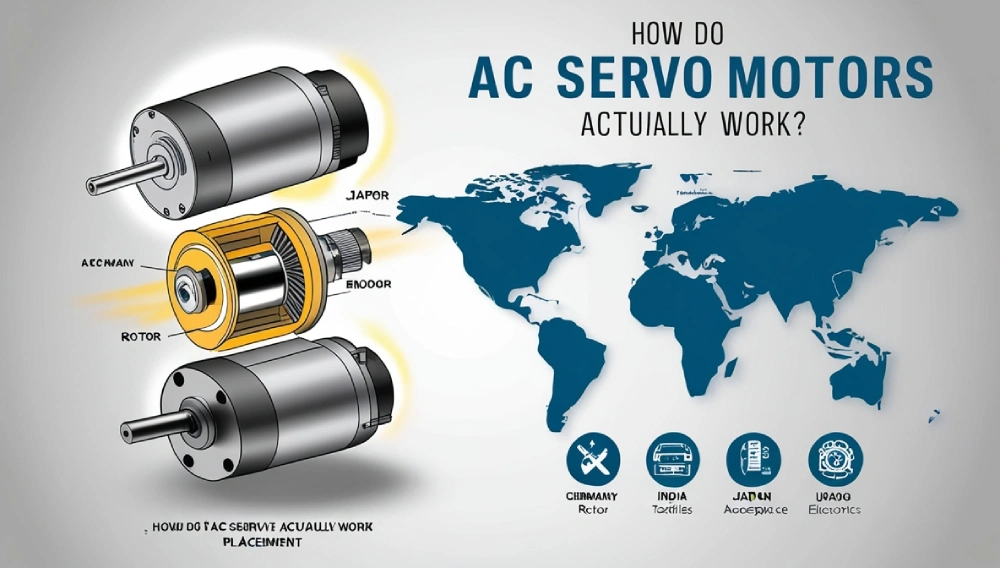

Key Components Inside an AC Servo Motor

| Component | Role |

| Stator | Creates a rotating magnetic field to drive the rotor |

| Rotor | The part that physically spins, driving mechanical parts |

| Encoder | Sends real-time feedback to the controller (like eyes for the motor) |

| Controller | The “brain” of the system that adjusts motion and performance |

Why AC Servo Motors Are Used Worldwide

From Germany to Japan, AC servo motors are everywhere—and for good reason:

Top Benefits:

- Energy Efficiency: Use up to 30% less energy than DC motors

- Precision Engineering: Positioning accuracy of ±0.01°, ideal for high-end electronics

- Tough in All Climates: Built to work in deserts, humidity, cold, or dusty environments

Real-World Use Cases:

| Country | Industry | Application |

| Germany | Automotive | BMW uses Yaskawa motors for robotic welding |

| India | Textiles | Delta ASDA-B3 motors in Surat’s silk looms |

| USA | Aerospace | SpaceX uses AC servos for satellite alignment |

| Japan | Electronics | Fanuc motors in Sony’s circuit board assembly lines |

How to Choose the Right AC Servo Motor

5-Step GEO-Smart Checklist:

Use this 5-step checklist to pick the perfect motor for your region and application:

1. Voltage & Frequency

- North America: 110V / 60Hz

- Europe: 220V / 50Hz

- India: 240V / 50Hz

2. Torque & Speed

- CNC machines: 10–20 Nm torque at 3000 RPM

- Conveyors: 5–10 Nm at 1500 RPM

3. Environmental Conditions

- Dusty? Get IP67-rated motors (e.g., for Middle Eastern factories)

- Humid? Opt for anti-corrosion coatings (perfect for Southeast Asia)

4. Budget & Brand

- Affordable: Leadshine ES-MH ($500) – great for small workshops

- Premium: Siemens SIMOTICS S-1FK7 ($2,500) – high-end European quality

5. Local Support

Choose brands with service centers in your region:

- Yaskawa in Pune

- Mitsubishi in Houston

Delta in Jakarta

How to install & Maintain an Servo Motor

Installation Tips

- Mounting: Use shock-resistant brackets in earthquake-prone areas (e.g., Japan)

- Wiring: Follow national codes (NEC in USA, IEC in Europe)

- Calibration: Use tuning software like Siemens SINAMICS or Delta ASDA-Soft

Maintenance Checklist

| Frequency | Task | Notes |

| Daily | Check for unusual noises or heat | Common in high-vibration zones like Indian mills |

| Monthly | Clean encoder lenses | Especially in dusty regions like Saudi Arabia |

| Yearly | Replace bearings | Required in humid climates like Thailand |

Troubleshooting by Region

| Problem | Region at Risk | Solution |

| Motor Overheating | UAE, desert regions | Add cooling fans or external heat sinks |

| Encoder Dust Clogging | India (during monsoon) | Clean weekly, use IP67 motors |

| Voltage Fluctuation | Philippines, rural areas | Install surge protectors or voltage stabilizers |

FAQs: Your Questions, Answered

Go for IP67-rated motors like the Delta ASDA-B3 with corrosion protection.

They’re optimized for 220V/50Hz and meet strict EU certifications (CE).

Absolutely! Compact options like Leadshine ES-MH work perfectly with 240V.

Install regenerative drives (e.g., Yaskawa SGD7S) to recycle braking energy.

no, not exactly. You can add an encoder to a regular induction motor, but it won’t match the positioning precision

Precision That Powers the World

AC servo motors are the invisible force behind the world’s most advanced machines—from electric car lines in Detroit to smart factories in Shenzhen. By choosing the right model for your voltage, workload, and environment, you’ll get faster performance, longer life, and lower energy bills.

About the Author:

Uthshab is a mechanical systems enthusiast and global SEO content writer specializing in automation. His writing blends hands-on experience with real-world examples to help engineers, hobbyists, and business owners make smart decisions.