Introduction

Have you ever wondered how large machines and equipment can run so smoothly and efficiently? One of the key players in this process is the Allen Bradley Variable Frequency Drive (VFD). These devices control the speed and torque of electric motors, making them essential for many industries. Whether you’re an engineer, technician, business professional, DIY enthusiast, or student, understanding Allen Bradley VFDs can help you appreciate their role in motor control and energy efficiency. In this article, we’ll explore what Allen Bradley VFDs are, how they work, their features, applications, and how to choose the right one for your needs.

What Are Allen Bradley VFDs?

Allen Bradley VFDs are devices that adjust the speed of electric motors by changing the frequency of the electrical power supplied to them. This adjustment allows for precise control over motor performance, which is crucial in various applications.

Why Are They Important?

- Energy Efficiency: By optimizing motor speed to match the load, Allen Bradley VFDs can significantly reduce energy consumption.

- Process Control: They provide accurate control over motor functions, improving the quality of processes in factories and other settings.

- Equipment Longevity: VFDs minimize mechanical stress on motors, extending their lifespan and reducing maintenance costs.

Allen Bradley VFDs, made by Rockwell Automation, are known for their robust build and advanced control features. Many models offer built-in PLC functionality, making it easy to integrate motor control with broader automation systems. Their user-friendly interfaces often include graphical displays and plug-and-play parameter settings. A key advantage of Allen Bradley drives is wide network compatibility (EtherNet/IP, DeviceNet, Modbus), enabling seamless communication with other equipment. They also tend to include safety functions like Safe Torque-Off (STO). Whether controlling a conveyor or a pump, these VFDs give precise speed control and detailed diagnostics.

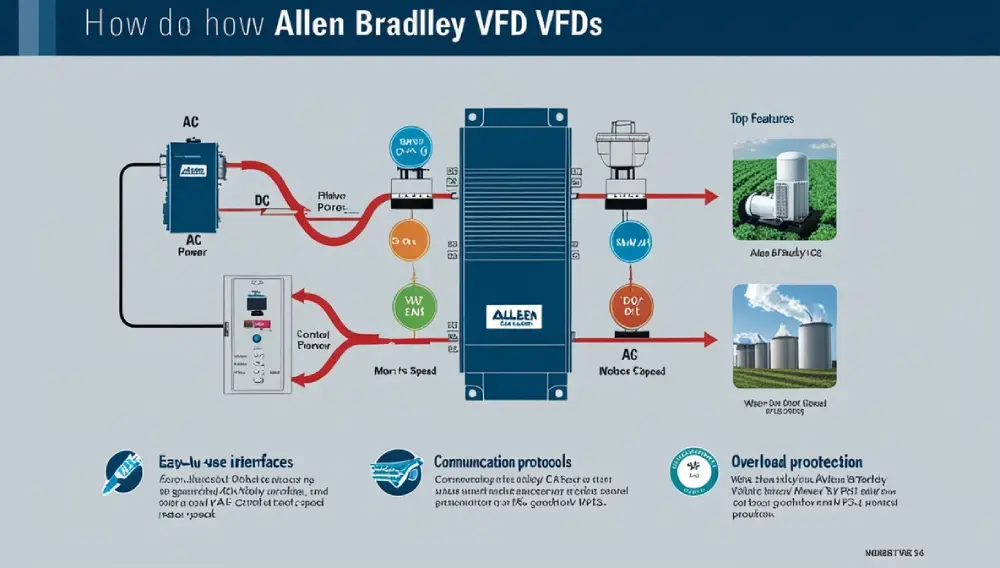

How Do Allen Bradley VFDs Work?

Basic Operation

The operation of Allen Bradley VFDs can be broken down into three main steps:

- Rectification: The incoming alternating current (AC) is converted into direct current (DC) using diodes.

- Filtering: Capacitors smooth out the DC power to provide a stable voltage.

- Inversion: The DC power is converted back into AC power at a variable frequency using transistors.

This process allows the VFD to control the speed of the motor effectively.

Key Features

- User-Friendly Interface: Many VFDs come with displays that make programming and monitoring easy.

- Communication Protocols: They support various communication methods, allowing them to integrate with other systems easily.

- Built-in Safety Features: These include overload protection and short-circuit protection, ensuring safe operation.

Applications of Allen Bradley VFDs

1. Industrial Automation

In manufacturing, Allen Bradley VFDs are used to control motors in conveyor systems, robotic arms, and other machinery. Their ability to adjust speed and torque enhances production efficiency and product quality.

2. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, VFDs control fan speeds and pump operations. This not only improves comfort levels but also leads to significant energy savings.

3. Water and Wastewater Management

VFDs are essential in water treatment facilities, where they regulate the speed of pumps to ensure efficient water circulation and treatment processes.

4. Agricultural Applications

Farmers utilize Allen Bradley VFDs in irrigation systems to optimize water usage and improve crop yields.

Choosing the Right Allen Bradley VFD

Selecting the right VFD is crucial for achieving optimal performance. Here are some factors to consider:

1. Motor Size

Make sure the VFD can handle the power rating of your motor. Check the specifications to find a suitable match.

2. Application Requirements

Consider the specific needs of your application. For example, a VFD for a pump may require different features than one for a conveyor belt.

3. Environmental Conditions

If the VFD will be exposed to dust, moisture, or extreme temperatures, select a model designed for those conditions.

4. Control Features

Look for models with programmable settings and communication interfaces that allow for integration with other systems.

Want to Read about Motor Starters vs Contactors.

Top Models of Allen Bradley VFDs

Some popular Allen Bradley VFD models include:

- PowerFlex 525: Known for its compact design and flexible communication options, ideal for various applications.

- PowerFlex 753: Offers advanced features for complex applications, including integrated safety functions.

- PowerFlex 4M: A cost-effective solution for simple applications, providing basic motor control functionalities.

Installation and Maintenance Tips

Installation Guidelines

- Read the Manual: Always start by reading the manufacturer’s installation manual for specific instructions.

- Wiring Diagrams: Follow the wiring diagrams provided to connect the motor leads and power supply properly.

- Safety First: Turn off all power before starting the installation and use appropriate personal protective equipment (PPE).

Maintenance Tips

- Regular Inspections: Check for dust accumulation and clean the VFD regularly.

- Monitor Performance: Keep an eye on the drive’s performance metrics to catch potential issues early.

- Software Updates: Ensure the firmware is up-to-date for optimal performance and security.

Frequently Asked Questions (FAQs)

Allen Bradley VFDs control the speed and torque of electric motors by adjusting the frequency and voltage of the power supplied to them. This improves energy efficiency and allows for better control over processes.

Allen Bradley VFDs are known for their reliability, user-friendly interfaces, and extensive support for communication protocols. While other brands may offer similar features, Allen Bradley often excels in integration and support.

You can purchase Allen Bradley VFDs from authorized distributors, online retailers, or directly from Rockwell Automation’s website.

Yes, with the proper guidelines and safety precautions, Allen Bradley VFDs can be installed relatively easily, especially with the help of the user manual.

Yes, most Allen Bradley drives support remote configuration and monitoring through Ethernet/IP or other supported protocols. Using Rockwell’s software tools, you can adjust parameters and check drive status without direct physical access to the VFD.

Conclusion

Allen Bradley VFDs are essential tools in modern motor control, offering significant benefits in energy efficiency, process control, and equipment longevity. Whether you’re working in industrial Automation, HVAC, or agriculture, understanding how to choose, install, and maintain these drives can greatly enhance your projects.

For more information or to explore purchasing options, consider visiting trusted suppliers or authorized distributors. Investing in Allen Bradley VFDs is a step toward optimizing your operations and achieving greater efficiency.

Allen Bradley VFDs are part of the broader VFD family—see how ABB VFDs compare in terms of functionality and energy savings.

3 thoughts on “Allen Bradley VFDs: Features, Applications & Buying Tips”