Introduction to DC Motors with Encoders

A DC motor with an encoder combines precise motion control with accurate position feedback, making it essential for:

✔ Robotics

✔ CNC machines

✔ 3D printers

✔ Automated manufacturing

✔ Medical devices

This guide explains how these smart motor systems work, their benefits, and how to choose the right one for your project.

Amazon Featured $ 14.99

Amazon Newest Arrivals

Why Use a DC Motor with an Encoder?

Key Advantages

- Precise position control (know exact motor position)

- Speed regulation (maintain consistent RPM)

- Closed-loop feedback (self-corrects errors)

- Better torque control (handles variable loads)

Applications

| Industry | Use Case |

|---|---|

| Robotics | Arm joint positioning |

| Automation | Conveyor belt control |

| Aerospace | Flight control surfaces |

| Automotive | Power seat adjustment |

| DIY Projects | Custom CNC builds |

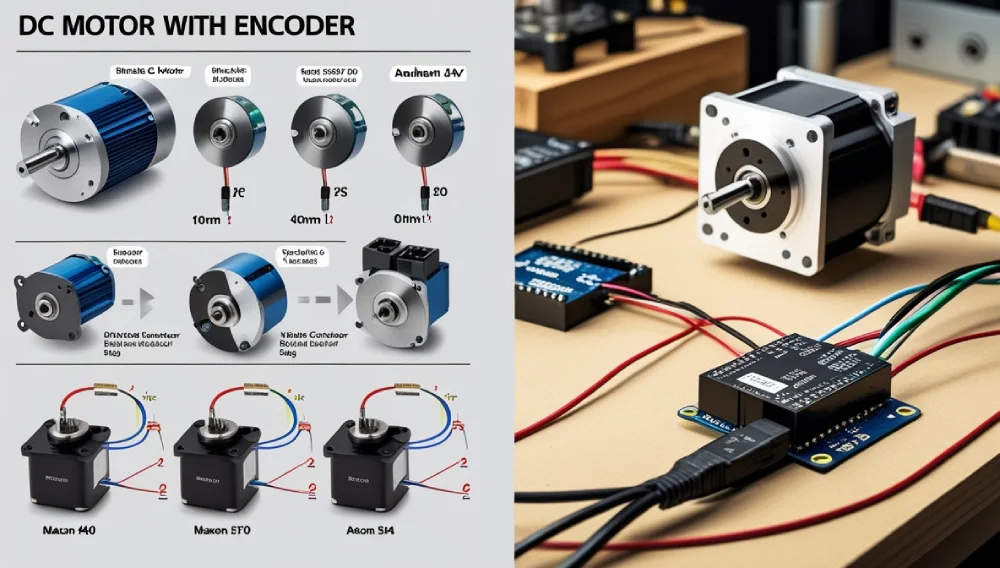

How DC Motor Encoders Work

Basic Components

- DC Motor: Provides rotational force

- Encoder: Tracks position/speed (optical or magnetic)

- Controller: Processes feedback signals

Encoder Types

- Incremental Encoders

- Measures relative movement

- Requires homing

- Lower cost

- Absolute Encoders

- Tracks exact position

- Remembers position after power loss

- More expensive

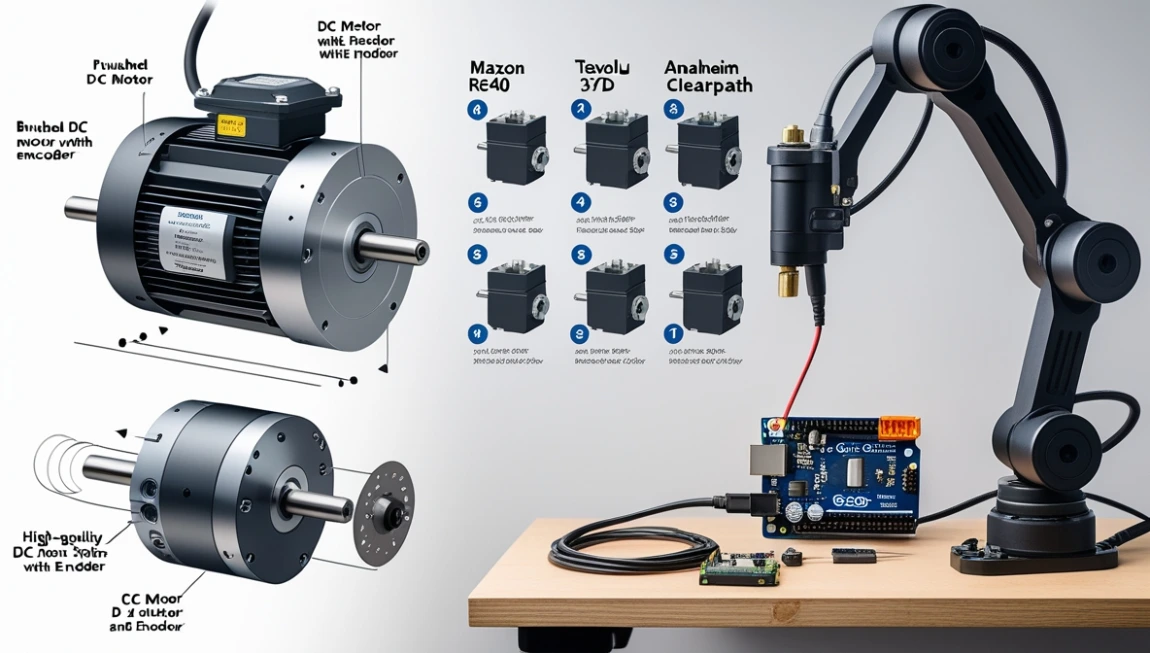

Top 5 DC Motors with Encoders (2024)

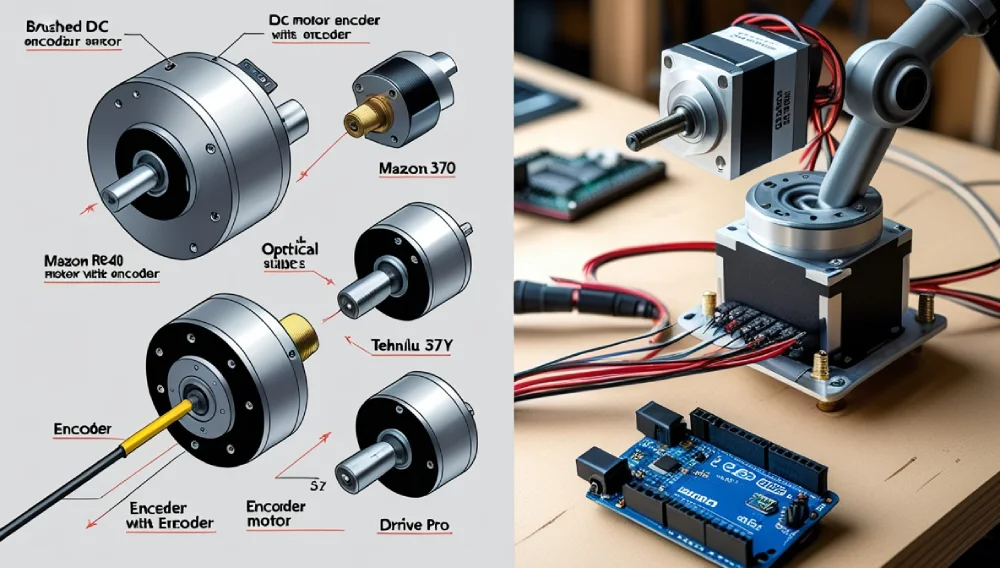

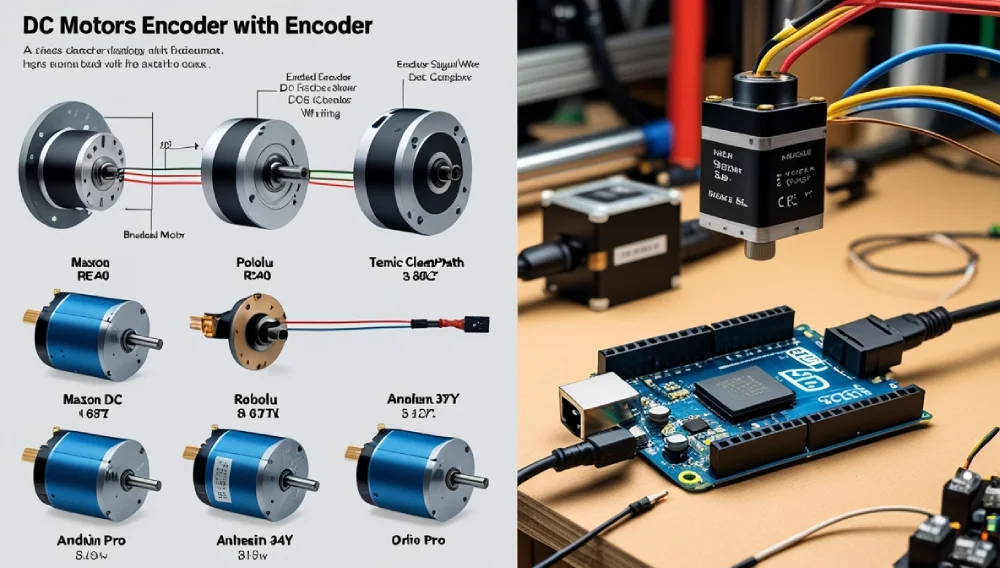

1. Maxon RE40 + Encoder

✔ Pros:

- Industrial-grade durability

- 500 CPR resolution

- Smooth operation

✔ Cons: - Expensive

- Requires separate driver

Best for: Professional robotics

2. Pololu 37Dx74L Gearmotor

✔ Pros:

- Affordable

- Built-in 64 CPR encoder

- Compact size

✔ Cons: - Plastic gears wear over time

- Low torque

Best for: Hobbyist projects

3. Teknic ClearPath-MCPV

✔ Pros:

- Integrated motor+driver+encoder

- No tuning required

- High torque density

✔ Cons: - Proprietary interface

- Premium pricing

Best for: Industrial automation

4. Anaheim Automation 34Y

✔ Pros:

- 1000-line encoder

- Brushless design

- Excellent speed control

✔ Cons: - Requires knowledgeable setup

- Large form factor

Best for: CNC applications

5. ODrive Pro Bundle

✔ Pros:

- Open-source ecosystem

- Supports FOC control

- High-resolution feedback

✔ Cons: - Complex configuration

- DIY assembly required

Best for: Advanced makers

Technical Specifications Explained

Critical Parameters

- Voltage Rating (12V/24V/48V)

- Encoder Resolution (CPR/PPR)

- Stall Torque (Nm or oz-in)

- No-Load Speed (RPM)

- Motor Type (Brushed/Brushless)

Encoder Resolution Guide

| CPR Range | Best For |

|---|---|

| 64-256 | Basic positioning |

| 500-1000 | Precision motion |

| 2000+ | High-end applications |

Buying Guide: Choosing the Right Motor

For Robotics

- Priority: Precision, compact size

- Recommended: Maxon RE40

- Budget: 200−200−500

For Industrial Use

- Priority: Reliability, torque

- Recommended: Teknic ClearPath

- Budget: 500−500−2000

For Hobby Projects

- Priority: Affordability

- Recommended: Pololu 37D

- Budget: 20−20−100

For CNC Machines

- Priority: Power, accuracy

- Recommended: Anaheim 34Y

- Budget: 300−300−800

Installation & Wiring

Basic Connections

- Motor Power (DC supply)

- Encoder Channels (A/B/Z to controller)

- Driver Signals (PWM/Direction)

- Grounding (Critical for noise reduction)

Common Pitfalls

- Ignoring encoder signal termination

- Underestimating power requirements

- Poor cable management causing noise

- Incorrect PID tuning

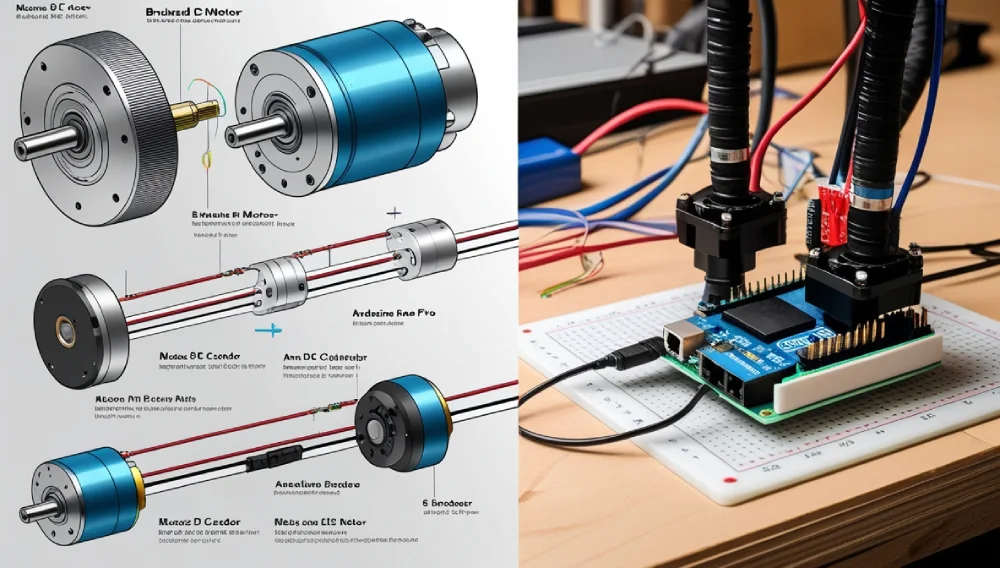

Personal Experience: Robotic Arm Project

When building a 6-axis robotic arm:

- Choose Maxon RE40 motors with 512 CPR encoders

- Implemented PID control in Arduino

- Achieved 0.1° positioning accuracy

- Learned that shielded cables prevent signal noise

Key takeaway: Higher encoder resolution dramatically improves precision but requires better controllers.

FAQs About DC Motors with Encoders

Q: Can I add an encoder to any DC motor?

A: Yes, with retrofit kits, but integrated units perform better.

Q: What’s better – optical or magnetic encoders?

A: Optical offers higher resolution; magnetic is more durable.

Q: How do I connect encoders to Arduino?

A: Use interrupt pins for A/B signals, or dedicated encoder ICs.

Q: Why is my encoder giving noisy readings?

A: Check cable shielding, grounding, and power supply quality.

Q: What’s the lifespan of these motors?

A: Brushless: 10,000+ hours; Brushed: 1,000-5,000 hours.

Future Trends in Smart Motors

Emerging technologies:

- Integrated IoT connectivity

- AI-based predictive maintenance

- Higher resolution magnetic encoders

- Modular motor/encoder systems

Final Recommendations

Best Overall: Maxon RE40 Series

Budget Pick: Pololu 37D Gearmotor

Plug-and-Play: Teknic ClearPath

Choose a DC motor with encoder when you need:

✅ Precise position control

✅ Consistent speed under load

✅ Closed-loop feedback

Have questions about your specific application? Ask below! ⚙️

Where to Buy:

- Robotics specialty stores

- Industrial automation suppliers

- Online marketplaces (Amazon, Digi-Key)

Read More: h 265 hdmi encoder

1 thought on “The Best DC Motor with Encoder”