Introduction

Imagine a robotic arm assembling a smartphone with pinpoint accuracy or a drone adjusting its propellers mid-flight for a smooth landing. These feats of precision are made possible by a DC servo motor—a compact, smart engine that powers countless automated systems. Whether you’re an engineer designing industrial robots, a student building a DIY project, or a business owner optimizing machinery, understanding DC servo motors is key to harnessing their potential.

In this guide, we’ll explain what a DC servo motor is, how it works, and why it’s a game-changer for Automation. You’ll discover its benefits, real-world uses, and tips for choosing and maintaining one. Let’s dive in!

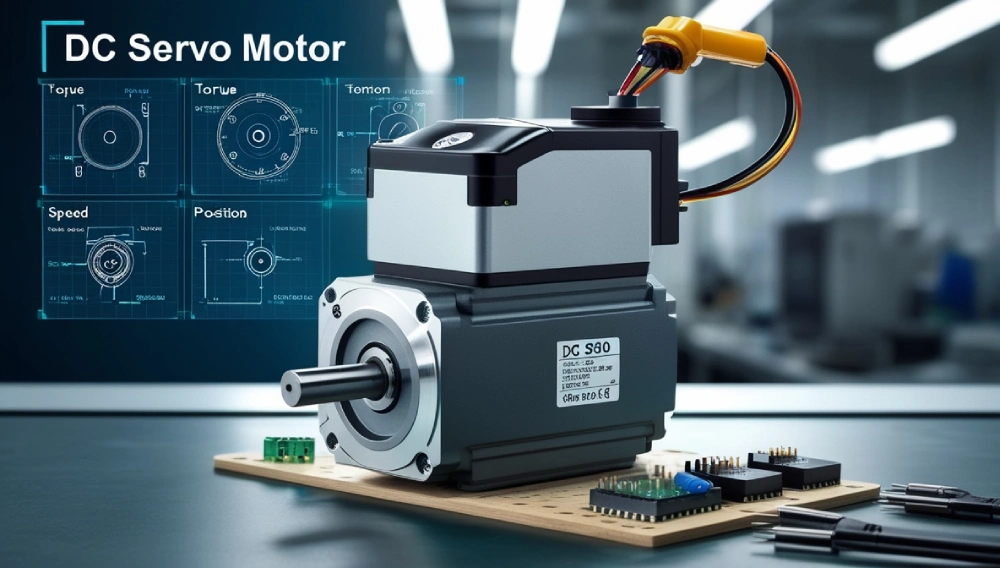

What is a DC Servo Motor?

A DC servo motor is a type of Servo motor designed for precise control of speed, position, or torque. Think of it as a smart motor that adjusts itself based on real-time feedback, much like how a thermostat maintains room temperature.

Key Components:

- DC Motor: Generates motion using direct current.

- Controller: Acts as the brain, sending commands to the motor.

- Feedback Sensor: Monitors the motor’s performance (e.g., encoder or potentiometer).

This trio forms a closed-loop system, where the Sensor constantly reports back to the controller, ensuring the motor stays on track.

How Does a DC Servo Motor Work?

Let’s break it down into simple steps:

- Command Input: You set a target (e.g., “Rotate 90 degrees”).

- Signal Processing: The controller calculates the power needed.

- Motion Execution: The DC motor starts moving.

- Feedback Check: The sensor measures actual movement.

- Adjustment: The controller tweaks power until the target is achieved.

Why This Matters:

Unlike regular motors, a DC servo motor corrects itself in real time. This makes it perfect for tasks demanding accuracy, like 3D printing or robotic surgery.

Key Features of DC Servo Motors

- High Precision: Hits targets within fractions of a degree.

- Fast Response: Adjusts speed or direction in milliseconds.

- Energy Efficient: Uses power only when needed, cutting costs.

- Durable: Built to last in tough environments (heat, dust, vibrations).

Benefits of Using DC Servo Motors

- Accuracy: Perfect for tasks like CNC machining or camera autofocus.

- Energy Savings: Reduces electricity bills by up to 40% compared to AC motors.

- Quiet Operation: Ideal for hospitals, labs, or home projects.

- Versatility: Scales from tiny DIY bots to industrial machinery.

Where Are DC Servo Motors Used?

| Industry | Application | Why DC Servo? |

| Robotics | Robotic arms, grippers | Precise joint movements |

| Manufacturing | CNC machines, conveyor belts | Consistent speed and accuracy |

| Aerospace | Drone navigation, satellite systems | Lightweight, reliable control |

| Consumer Tech | Camera lenses, gaming controllers | Smooth, responsive adjustments |

How to Choose the Right DC Servo Motor

5-Step Checklist:

- Power Needs: Match voltage and torque to your project.

- Feedback Type: Optical encoders for precision, potentiometers for simplicity.

- Size: Compact motors for small devices; heavy-duty for factories.

- Budget: Entry-level (under 50) vs. industrial (upto 50) vs. industrial(upto500).

- Brand Reputation: Stick with trusted names like Maxon or Faulhaber.

Pro Tip: Check compatibility with your existing controllers (e.g., Arduino, Raspberry Pi).

Installing & Maintaining Your DC Servo Motor

Installation Guide:

- Mount Securely: Use brackets to reduce vibrations.

- Wire Correctly: Connect power, ground, and signal cables as per the manual.

- Calibrate: Run a test cycle to fine-tune the feedback system.

Maintenance Tips:

- Monthly Checks: Clean dust from vents.

- Annual Lubrication: Apply grease to gears (if applicable).

- Troubleshooting:

- Motor not moving? Check wiring and power supply.

- Overheating? Reduce load or improve cooling.

FAQs: Your Questions Answered

DC motors use direct current and are smaller/quieter. AC motors handle higher power but are bulkier.

Yes! They only draw power when adjusting, unlike always-on AC motors.

Absolutely! Models like the SG90 are popular for Arduino/Raspberry Pi builds.

5-10 years with proper care. Avoid overloading and keep them clean.

Conclusion: Ready to Power Your Projects?

DC servo motors are the silent heroes behind precise automation, from factory floors to your hobby workbench. By understanding their benefits and applications, you can choose the right motor to elevate your projects.

Next Steps:

- Explore top-rated DC servo motors on Amazon or specialized retailers.

- Join forums like Robotics Stack Exchange for expert advice.

- Share your creations with #DCservo on social media!

About the Author:

John Carter is a robotics engineer with a decade of experience in automation. She’s passionate about making advanced tech accessible to everyone.

4 thoughts on “DC Servo Motor| Precision Control| Benefits| Applications Explained”