Why High Torque Servo Motors?

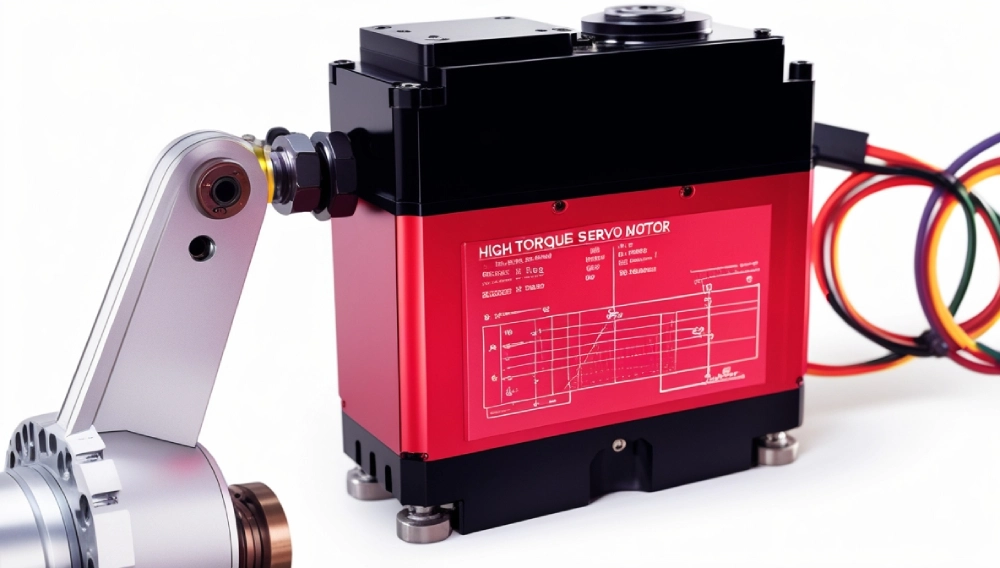

Imagine a robotic arm lifting car parts on an assembly line or a CNC machine carving steel with surgical precision. These feats are powered by high torque servo motors—motors designed to handle heavy loads and maintain pinpoint accuracy. But what exactly are they, and how do they work?

A high torque servo motor combines raw rotational force (torque) with smart feedback systems, making it ideal for tasks where power and precision matter. Unlike standard motors, these high-power servo motors adjust their performance in real time, ensuring they never miss a beat. Whether you’re building a robot, automating a factory, or tackling a DIY project, understanding strong servo motors will help you choose the right tool for the job. Let’s dive in!

What Is a High Torque Servo Motor?

A high torque servo motor is an electric motor that delivers exceptional rotational force while maintaining precise control over speed and position. Think of it as a motor that “listens” to feedback sensors to adjust its movements—like a driver steering a car based on GPS directions.

Key Features:

- High Torque: Can lift heavy loads (e.g., 50 kg/cm or more).

- Closed-Loop Control: Uses encoders to self-correct errors.

- Precision: Moves to exact angles (e.g., ±0.1° accuracy).

How Do High Torque Servo Motors Work?

Here’s a simplified breakdown:

- Command Signal: A controller tells the motor where to move.

- Motor Activation: The motor turns its shaft toward the target position.

- Feedback Check: Sensors (encoders) monitor the shaft’s actual position.

- Adjustment: If there’s a mismatch, the motor corrects itself instantly.

Why It’s Better Than Standard Motors:

Standard motors spin freely, but high torque servo motors adjust on the fly. For example, if a robotic arm hits resistance, the motor increases power to push through without stalling.

Key Features of High Torque Servo Motors

- Muscle for Heavy Lifting: Handle loads that would stall weaker motors.

- Smart Control: Built-in sensors ensure movements stay accurate.

- Energy Efficiency: Use power only when adjusting position.

- Durability: Built to withstand heat, dust, and constant use.

Top Benefits of Using High Torque Servo Motors

- No More Guesswork: Perfect for tasks like lifting, pushing, or rotating heavy objects.

- Faster Operations: Achieve complex movements quickly.

- Long Lifespan: Rugged design reduces wear and tear.

- Versatility: Used in factories, hospitals, and even theme park rides!

Where Are High Torque Servo Motors Used?

From assembly lines to your garage, these motors power critical tasks:

- Industrial Robots: Lift car engines or assemble electronics.

- CNC Machines: Carve metal, wood, or stone with precision.

- Medical Equipment: Adjust surgical tools or MRI machines.

- DIY Projects: Build automated gates or heavy-duty 3D printers.

Real-World Example: Tesla’s factories use them to assemble electric car batteries efficiently.

How to Choose the Right High Torque Servo Motor

Follow this checklist to find your perfect match:

- Torque Needs: Calculate required force (load weight × distance from shaft).

- Speed: Higher RPM = faster movements (but may reduce torque).

- Voltage: Match your power supply (e.g., 24V or 48V).

- Feedback Type: Optical encoders (more precise) vs. potentiometers (affordable).

- Size: Compact models (e.g., 40mm frame) vs. industrial-sized (100mm+).

Pro Tip: For CNC machines, aim for at least 30 kg/cm torque.

Installing a High Torque Servo Motor

Tools Needed: Motor, driver, power supply, controller (Arduino/PLC).

- Mount the Motor: Secure it with bolts to prevent vibration.

- Connect Wires:

- Motor → Driver (PWM, ground, power).

- Driver → Controller.

- Calibrate: Use software to set zero position and torque limits.

Maintenance Tips for Longevity

- Keep It Cool: Add heat sinks or fans to prevent overheating.

- Lubricate Gears: Use light grease every 6 months.

- Check Connections: Loose wires cause erratic movements.

FAQs: Your Questions, Answered

Servo motors use feedback for precision; steppers move in fixed steps without feedback.

Yes! Just avoid max load continuously and ensure cooling.

It’s holding position against resistance—normal unless overheating.

10,000+ hours with proper care

Conclusion: Power Your Projects with Precision

High torque servo motors are the backbone of industries where strength meets smarts. Whether you’re automating a factory or building a robot, these motors deliver reliability and raw power.

Ready to upgrade? Explore our top-rated high torque servo motors and take your projects from “good” to “industrial-grade”!

Author Bio:

john Carter is a mechanical engineer with 8+ years of experience in automation systems. He’s passionate about helping engineers and hobbyists master motor technology.

1 thought on “High Torque Servo Motor Explained: Boost Power| Precision for Heavy-Duty Projects”