Introduction: What Makes High Torque Stepper Motors Special?

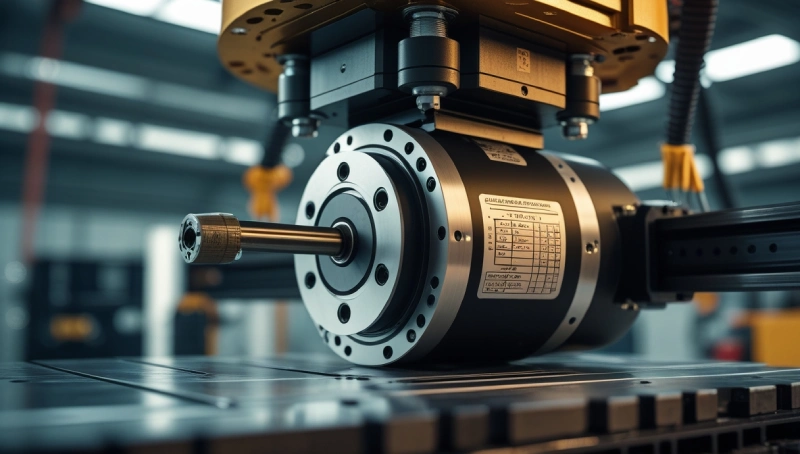

Imagine a motor that can lift heavy machinery parts, carve metal with pinpoint accuracy, or power a robotic arm—all while maintaining precise control. That’s the magic of a high torque stepper motor. Unlike standard stepper motors, these powerhouse motors are built to handle demanding tasks where strength and precision matter.

A stepper motor with high torque combines precise step-by-step movement with extra muscle, making it ideal for CNC machining, 3D printing, and industrial robots. But how does it work, and why should you choose one? In this guide, we’ll break down the advantages of high torque stepper motors, explore real-world uses, and show you how to choose a high torque stepper motor that fits your needs. Let’s dive in!

What Is a High Torque Stepper Motor?

A high torque stepper motor is a type of Electric motor designed to deliver exceptional rotational force (torque) while maintaining precise control over movement. Think of it like a weightlifter who can lift heavy barbells and balance a pencil on their finger—strength meets precision.

Key Features:

- Holding Torque: Ranges from 1 N·m to 15 N·m (or higher).

- Step Accuracy: Moves in exact increments (e.g., 1.8° per step).

- Closed-Loop Systems: Some models use sensors to self-correct missed steps.

How Do High Torque Stepper Motors Work?

Here’s a simple breakdown of their operation:

- Pulse Signals: A controller sends electronic pulses to the motor.

- Magnetic Coils: These pulses energize coils, creating magnetic fields.

- Rotor Movement: The rotor turns to align with the fields, moving in precise steps.

- Feedback (Optional): Closed-loop models use encoders to verify position.

Why High Torque?

More torque means the motor can handle heavier loads without stalling. For example, a CNC machine cutting metal needs a high torque motor to push through resistance smoothly.

Key Benefits of High Torque Stepper Motors

- Muscle for Heavy Loads: Lift, push, or rotate heavy objects effortlessly.

- Precision Control: Perfect for tasks requiring exact positioning (e.g., 3D printer extruders).

- Energy Efficiency: Maintains position without continuous power.

- Durability: Built to withstand harsh industrial environments.

Where Are High Torque Stepper Motors Used?

From factories to labs, these motors power critical tasks:

- CNC Machines: Carve metal, wood, or plastic with precision.

- Robotic Arms: Lift and position heavy components in assembly lines.

- Medical Devices: Control surgical robots or MRI machine parts.

- 3D Printers: Handle large builds with dense materials.

- Conveyor Systems: Move heavy packages in warehouses.

Real-World Example: Automotive factories use them to assemble engines with micron-level accuracy.

How to Choose the Right High Torque Stepper Motor

Follow this checklist to find your perfect match:

- Torque Needs: Calculate the force required (e.g., load weight x distance from shaft).

- Voltage & Current: Match your power supply (e.g., 24V or 48V systems).

- Frame Size: NEMA 17 (compact) to NEMA 34 (industrial) standards.

- Open vs. Closed Loop: Closed-loop for error correction in critical tasks.

- Budget: High-torque motors cost more but reduce long-term errors.

Pro Tip: For CNC machines, aim for at least 2 N·m torque.

Installation Guide: Wiring a High Torque Stepper Motor

Tools Needed: Motor, driver (e.g., DM542T), power supply, controller (Arduino/CNC board).

- Connect Motor to Driver:

- Coil A+ and A- to driver outputs.

- Coil B+ and B- to remaining outputs.

- Link Driver to Controller:

- Pulse (PUL+/-) and Direction (DIR+/-) wires to controller pins.

- Power Up:

- Driver to 24V–48V power supply.

Maintenance Tips for Longevity

- Keep Cool: Add heat sinks or fans to prevent overheating.

- Lubricate Bearings: Use light machine oil annually.

- Check Connections: Loose wires cause jittery movements.

FAQs: Your Questions, Answered

Yes! Just ensure proper cooling and avoid max torque continuously.

For precision + affordability, yes. Servos excel in high-speed tasks.

Resonance—use a microstepping driver to smooth motion.

10,000+ hours with regular maintenance.

Conclusion: Power Your Projects with Confidence

High torque stepper motors are the backbone of industries where precision meets brute strength. Whether you’re crafting a DIY CNC machine or optimizing a factory line, these motors deliver reliability and power. Ready to upgrade? Explore our top-rated high torque stepper motors and take your projects to the next level!

Author Bio:

Mark Rivera is a mechanical engineer with 12+ years of experience in industrial automation. He’s passionate about helping engineers and hobbyists master motion control tech.

1 thought on “High Torque Stepper Motor: Precision Power for Demanding Applications”