Introduction

Imagine controlling an entire factory’s operations with just a few taps on a screen—or diagnosing a machine issue from your smartphone. That’s the power of an HMI System (Human-Machine Interface). These systems are the backbone of modern automation, making complex industrial processes simple to monitor and control.

Whether you’re an engineer, a student, or just curious about automation, this guide will break down:

✔ What an HMI System is

✔ How it works

✔ Key benefits & real-world applications

✔ The best HMI systems for different industries

Let’s dive in!

What Is an HMI System?

An HMI System is a digital interface that connects humans to machines, allowing operators to:

- Monitor real-time data (temperature, pressure, speed)

- Control equipment (start/stop machines, adjust settings)

- Diagnose issues (alerts for malfunctions)

Example: Think of an HMI like your car’s dashboard—it shows speed, fuel levels, and lets you control AC, all in one place.

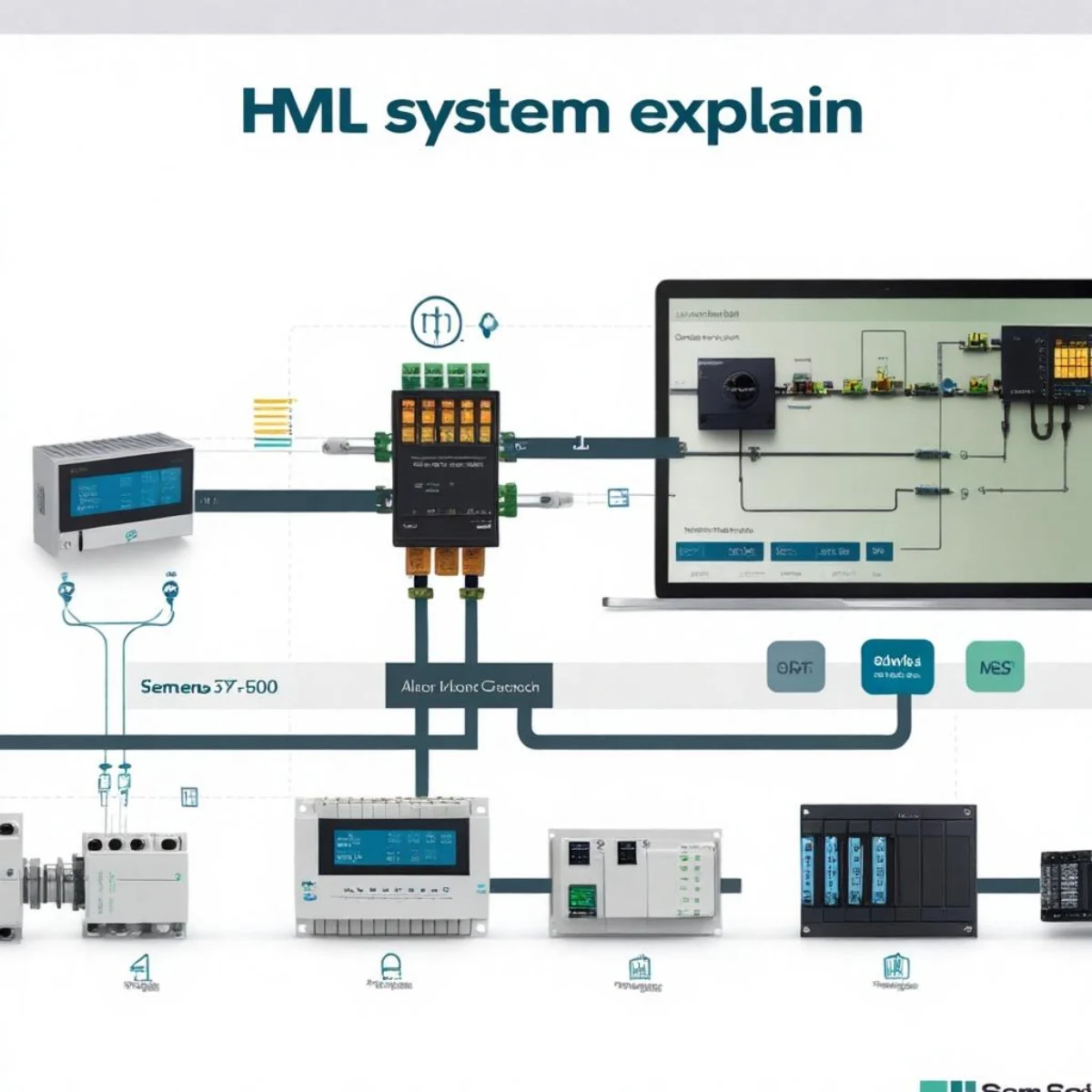

Key Components of an HMI System

- Display Panel – Touchscreen or LED screen

- Control Software – SCADA, PLC-compatible programs

- Communication Protocols – Ethernet, Modbus, Profibus

- Input/Output Modules – Links to sensors & actuators

How Does an HMI System Work?

- Data Collection – Sensors on machines send real-time data (e.g., temperature, pressure).

- Data Processing – The HMI system organizes and displays this data.

- User Interaction – Operators use the touchscreen to adjust settings or respond to alerts.

- Machine Control – Commands are sent back to the equipment (e.g., slow down a conveyor belt).

Example: In a water treatment plant, an HMI system monitors tank levels and automatically adjusts pumps to prevent overflow.

Types of HMI Systems

| Type | Best For | Example Use |

| Text-Based HMI | Simple machines | Basic status displays (e.g., “Motor ON/OFF”) |

| Graphical HMI | Factories, smart homes | Touchscreen control panels |

| Web-Based HMI | Remote monitoring | Cloud-based dashboards accessible via phone |

Modern trend: Most industries now use touchscreen HMIs for better usability.

Top 5 Benefits of HMI Systems

✅ Improved Efficiency – Automate tasks & reduce human error.

✅ Real-Time Monitoring – Instantly detect machine issues.

✅ Remote Access – Control systems from anywhere (via mobile/PC).

✅ Better Safety – Alerts for overheating, leaks, or malfunctions.

✅ Data Logging – Track performance trends for maintenance.

Case Study: A car factory reduced downtime by 30% after installing an HMI system that predicted machine failures.

Where Are HMI Systems Used?

🏭 Manufacturing – Assembly lines, robotic arms

⚡ Energy & Power Plants – Grid monitoring, turbine control

🚗 Automotive – Engine diagnostics, quality checks

🏥 Healthcare – Medical equipment monitoring

🏡 Smart Homes – HVAC, lighting, security control

How to Choose the Best HMI System

Ask these questions before buying:

- Screen Type – Touchscreen or button-based?

- Connectivity – Does it support Ethernet, Wi-Fi, or Modbus?

- Durability – Waterproof? Dustproof? (Important for factories)

- Software Compatibility – Works with your PLC/SCADA system?

Best HMI System Brands (2024)

| Brand | Best For | Price Range |

| Siemens Simatic | Heavy industry | $$$ |

| Allen-Bradley PanelView | Manufacturing | $$$$ |

| Schneider Magelis | Energy & utilities | $$ |

| Mitsubishi GOT | High-speed automation | $$$ |

FAQs About HMI Systems

No—the HMI needs a PLC (or similar controller) to process machine data.

5–10 years with proper maintenance.

Yes, if you use firewalls, encryption, and regular updates.

Yes! Apps like Ignition SCADA turn tablets into HMIs.

Conclusion

HMI Systems are revolutionizing industries by making automation smarter, safer, and more efficient. Whether you’re running a factory or just love tech, understanding HMIs helps you harness the power of modern control systems.

Ready to explore HMI solutions? Check out top brands like Siemens or Allen-Bradley, and see how automation can transform your operations!

Read More?

1 thought on “HMI Systems Explained: How They Power Automation | Boost Efficiency”