Introduction

Imagine a motor so small and precise it can move a camera lens by a fraction of a millimeter or guide a medical syringe with life-saving accuracy. That’s the magic of a micro stepper motor! These tiny devices are the unsung heroes in gadgets and machines where precision matters most. Whether you’re an engineer designing a robot, a hobbyist building a 3D printer, or a student curious about automation, this guide will explain everything you need to know about micro stepper motors—how they work, where they’re used, and how to pick the right one. Let’s dive in!

What Is a Micro Stepper Motor?

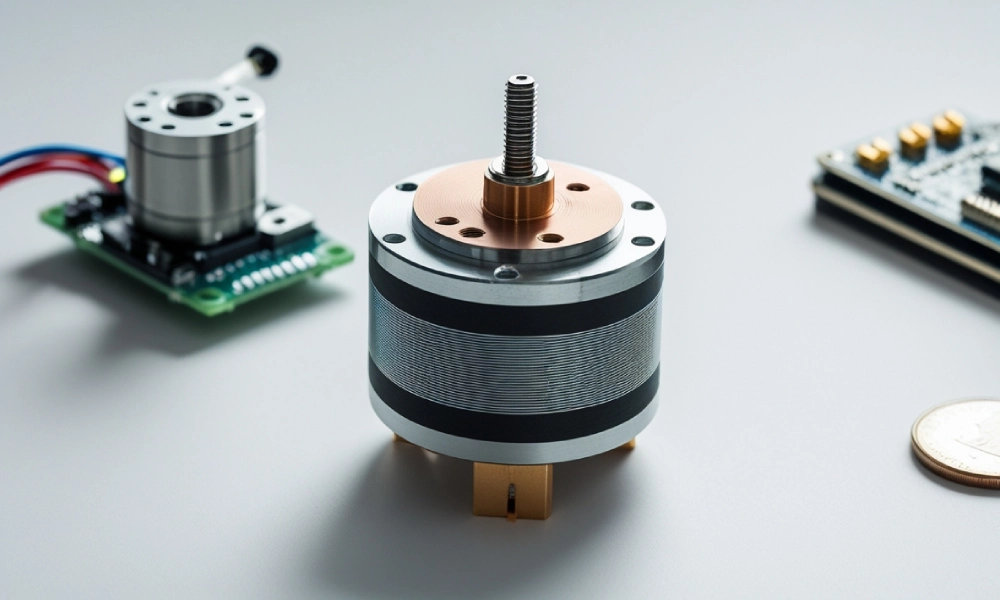

A micro stepper motor is a compact, electric motor designed to move in small, precise steps instead of spinning freely like a regular motor. Each “step” is controlled by electrical pulses, allowing it to position parts accurately—think of it like a robot’s muscle that flexes exactly as programmed.

Key Features:

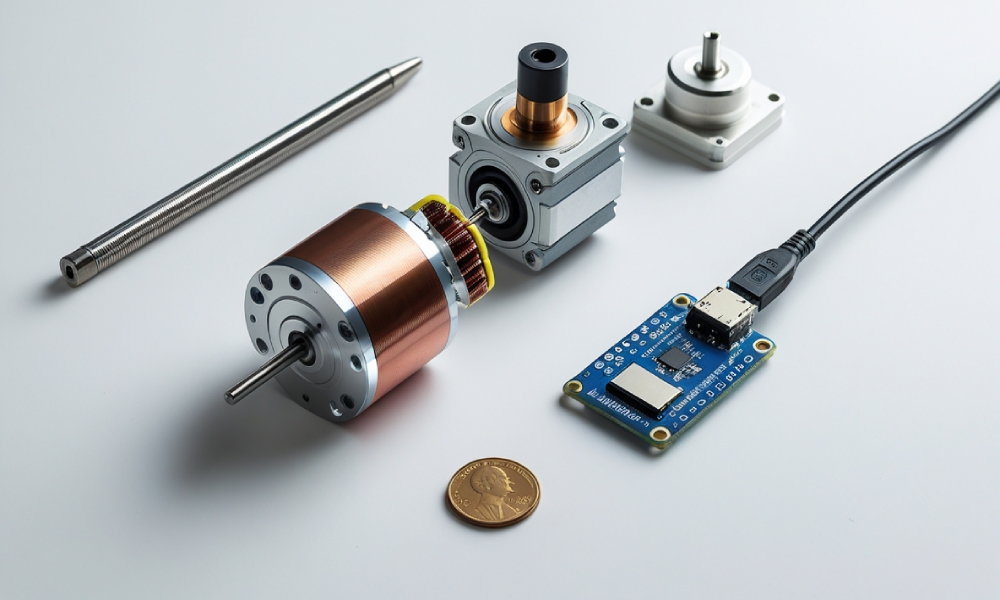

- Size: Often smaller than a coin.

- Precision: Moves in fractions of a degree.

- Control: Needs a driver circuit to operate.

- Uses: Common in robotics, medical tools, and cameras.

How Do Micro Stepper Motors Work?

Let’s break it down simply:

- Electrical Pulses: When you send a pulse to the motor, it activates coils inside.

- Magnetic Fields: These coils create magnetic forces that push/pull a rotor (the spinning part).

- Step Movement: Each pulse turns the rotor by a fixed angle (like 1.8° or even 0.9°).

- Repeat: More pulses mean more rotation—no guessing!

Why It’s Better Than Regular Motors:

- Accuracy: Perfect for tasks like aligning a 3D printer nozzle.

- Low Power: Sips energy, great for battery-powered devices.

- No Feedback Needed: It knows its position by counting steps.

Key Features: Pros and Cons

Pros

✅ Super precise movements.

✅ Compact and lightweight.

✅ Works in open-loop systems (no sensors required).

✅ Affordable for small-scale projects.

Cons

❌ Lower torque (strength) compared to bigger motors.

❌ Can vibrate or get noisy at high speeds.

❌ Needs a driver circuit, which adds complexity.

Where Are Micro Stepper Motors Used?

These motors shine in jobs where details matter:

- Medical Devices: Insulin pumps, surgical robots.

- Cameras: Autofocus and lens adjustments.

- Robotics: Tiny joints for robotic arms.

- 3D Printers: Precise filament control.

- DIY Projects: Automated plant waterers, mini CNC machines.

Real-World Example:

A hobbyist might use a micro stepper motor to build a custom clock with moving hands that never miss a second!

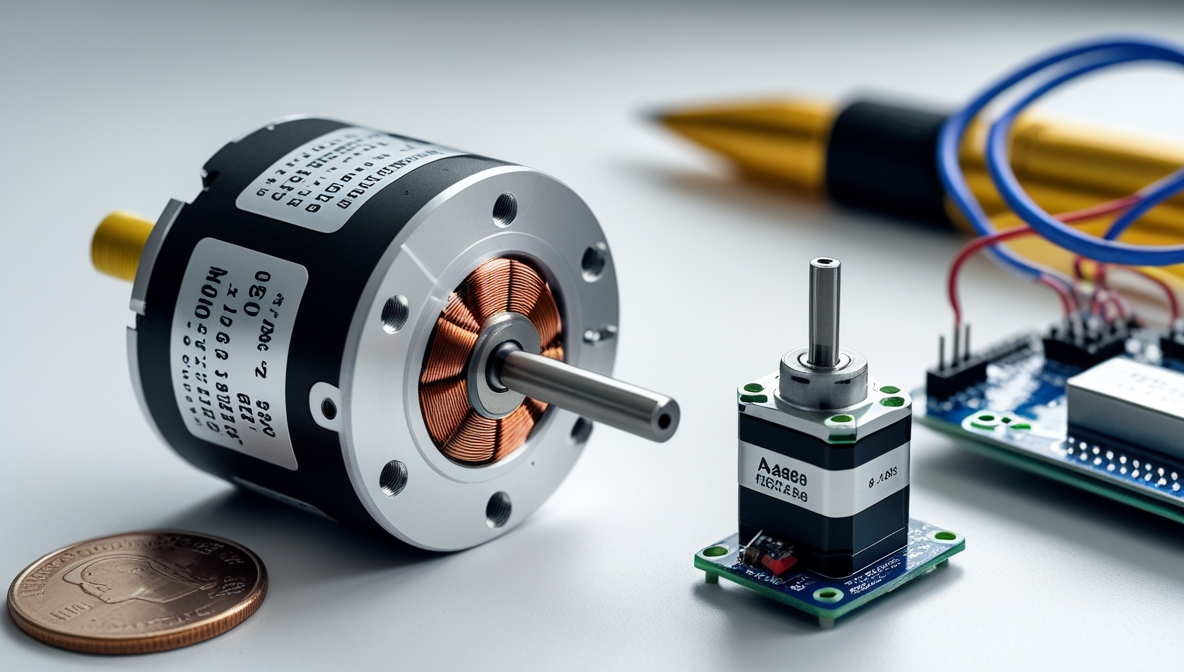

Types of Micro Stepper Motors

Not all tiny Stepper motors are the same! Here’s a quick breakdown:

- Permanent Magnet (PM): Budget-friendly, good for basic tasks.

- Variable Reluctance (VR): Rare but used in industrial settings.

- Hybrid: Combines PM and VR for top performance (most common).

Phases Matter Too:

- 2-Phase: Simple and widely used (e.g., in 3D printers).

- 4-Phase: Smoother motion but needs more complex drivers.

How to Control a Micro Stepper Motor

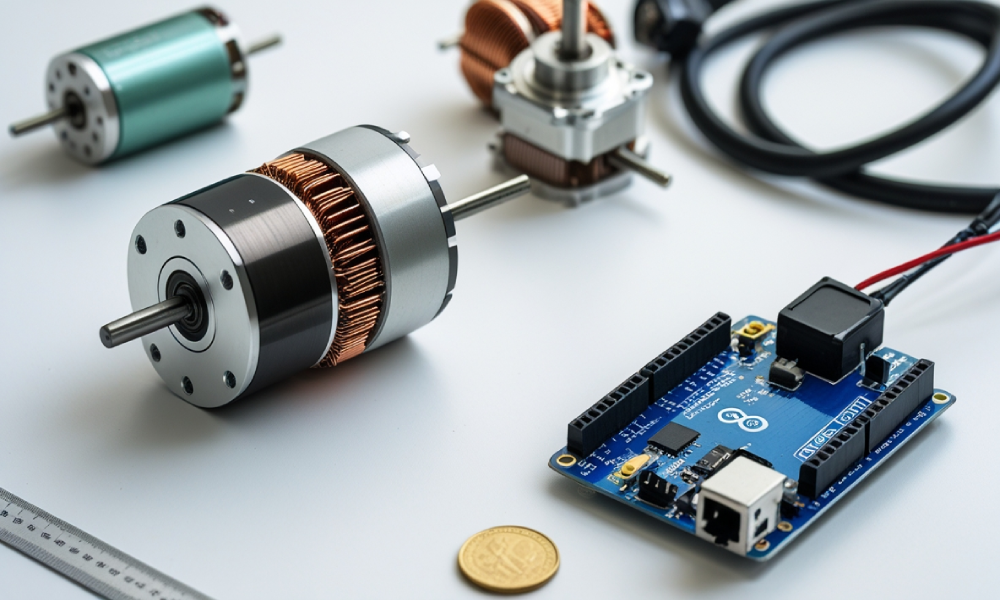

You’ll need two things: a driver circuit and a controller (like an Arduino).

Step-by-Step Setup:

- Pick a Driver: Popular options: A4988 stepper motor driver or DRV8825.

- Wire It Up: Connect the motor to the driver and a power source.

- Code It: Use Arduino to send pulse signals (Example: digitalWrite(pin, HIGH)).

Pro Tip: Start with a pre-made kit if you’re new—it’ll save time!

Buying Guide: What to Look For

Choosing the right motor depends on your project:

- Voltage/Current: Match your power supply (e.g., 5V for Arduino).

- Steps Per Revolution (SPR): Higher SPR = smoother motion.

- Size: Measure your space (common sizes: NEMA 8, NEMA 11).

- Torque: Check the motor’s strength (in oz-in or N-cm).

Question to Ask:

“Do I need it to lift a camera lens or just turn a tiny gear?”

Top Micro Stepper Motor Picks

While brands vary, these are trusted options:

- NEMA 8 Hybrid Stepper: Great for CNC machines.

- 28BYJ-48 with Driver: Affordable for Arduino projects.

- Lin Engineering 4218L: Medical-grade precision.

Conclusion

Micro stepper motors are tiny powerhouses that make precision possible in everything from robots to medical tools. By understanding their types, uses, and control methods, you can unlock endless DIY or professional projects. Got questions? Check out the FAQs below or explore our guide on Stepper Motors vs. Servo Motors next!

FAQs

It’s smaller, uses less power, and excels at precise, low-torque tasks.

Autofocus in cameras or moving parts in DIY robots.

Higher steps (e.g., 200 vs. 48) mean finer control but slower speed.

Autofocus in cameras or moving parts in DIY robots.

No—opt for larger steppers or servo motors for high-torque jobs.

3 thoughts on “What is a Micro Stepper Motor? Uses| Control Tips & Where to Buy”