Introduction

Motor starters and contactors are essential components in electrical systems, especially in automation and control applications. They help manage the operation of electric motors safely and efficiently. If you’re an engineer, technician, business owner, DIY enthusiast, or student, understanding these devices is crucial. In this article, we will explore what motor starters and contactors are, their types, applications, and how they work together. By the end, you’ll have a solid grasp of these components and be ready to make informed decisions if you’re looking to purchase them.

What are Motor Starters?

Motor starters are devices used to start and stop electric motors safely. They help protect the motor from damage due to overloads or short circuits.

Types of Motor Starters

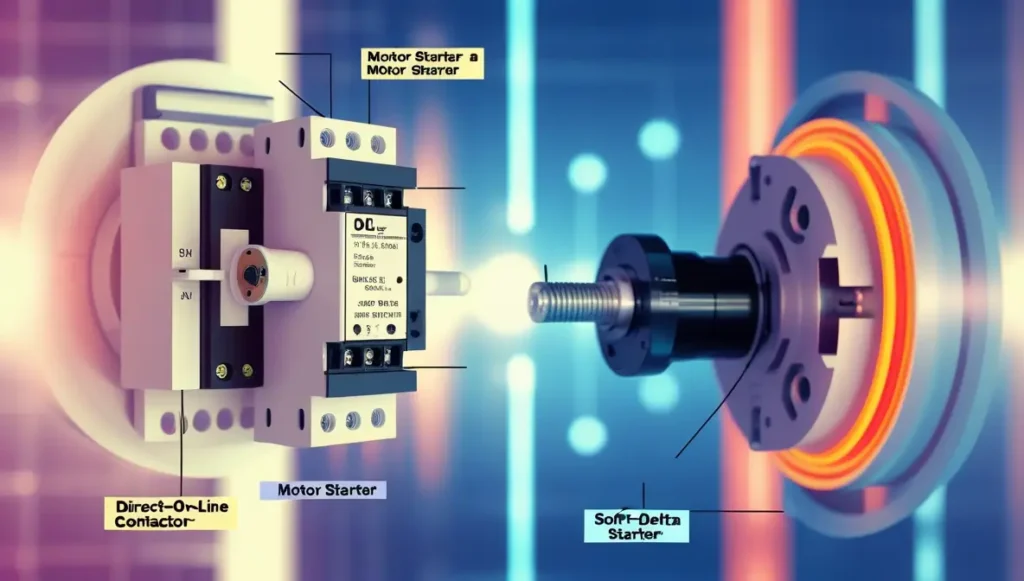

- Direct-On-Line (DOL) Starters: The simplest type, connecting the motor directly to the power supply. Best for small motors (up to 5 HP).

- Star-Delta Starters: Used for larger motors to reduce the starting current. Initially connects the motor in a star configuration, then switches to delta after starting.

- Soft Starters: Gradually increase the voltage to the motor, allowing for a smoother start. Useful for applications where sudden starts could cause mechanical stress.

Applications of Motor Starters

- Industrial Machinery: Used in conveyor belts, pumps, and fans.

- HVAC Systems: Control the operation of compressors and blowers.

- Home Appliances: Found in washing machines and refrigerators.

What are Contactors?

Contactors are electrically controlled switches used to control power circuits. They are designed to switch electrical loads on and off.

Differences Between Contactors and Relays

- Contactors: Handle larger currents and are used for motor control.

- Relays: Typically used for lower voltage applications and signal switching.

Applications of Contactors

- Motor Control: Used alongside motor starters to control the power supply.

- Lighting Control: Manage large lighting systems in commercial buildings.

- Heating Systems: Control electric heaters and boilers.

Motor starters and contactors are complementary parts of an electric motor control system. A contactor is a heavy-duty switch that energizes or de-energizes a motor circuit, while a motor starter includes that switch plus an overload relay. In practice, when you press a start button, the contactor closes the circuit, and the motor starts running; the starter’s overload protection remains active in the background. This partnership means you can remotely control motors (via contactors) and still protect them from overheating (via starters). Properly pairing the right starter and contactor for your motor’s power and environment is key to reliability.

How Motor Starters and Contactors Work Together

Motor starters and contactors often work in tandem to ensure safe motor operation. The motor starter provides the necessary protection, while the contactor allows for the switching of the motor on and off. When a motor is started, the contactor closes, allowing electricity to flow through the starter and to the motor.

Example Scenario

In a factory setting, a DOL starter may be used with a contactor to start a conveyor belt motor. When the operator presses the start button, the contactor closes, and the motor begins to run, allowing materials to move along the belt.

Choosing the Right Motor Starter and Contactor

When selecting motor starters and contactors, consider the following factors:

- Load Requirements: Understand the power and current ratings of your motor.

- Voltage: Ensure the starter and contactor match the motor’s voltage.

- Environment: Consider factors like temperature, humidity, and exposure to dust or chemicals.

Common Issues and Troubleshooting Tips

Even with proper selection and installation, issues can arise. Here are some common problems and their solutions:

- Motor Won’t Start: Check for power supply issues or faulty contactors.

- Overheating: Ensure the motor starter is rated for the load and check for obstructions.

- Frequent Tripping: This may indicate an overload condition; check the motor’s load and starter settings.

Conclusion

Understanding motor starters and contactors is vital for anyone involved in electrical systems. These components play a crucial role in ensuring the safe and efficient operation of motors. Whether you’re a professional or a hobbyist, knowing how to choose and troubleshoot these devices will enhance your projects and operations.

If you’re interested in purchasing motor starters and contactors, explore our range of products tailored to meet your needs. Whether you’re looking for a simple DOL starter or a sophisticated soft starter, we have options for everyone!

FAQ

A motor starter is used to start and stop electric motors safely, protecting them from overloads.

Consider the motor’s power rating, the type of application, and the environment in which it will operate.

While it’s possible, using a contactor without a motor starter can expose the motor to risks like overload and damage.

Contactors handle larger currents for motor control, while relays are used for lower voltage applications and signal switching.

Always ensure that the motor starter and contactor are rated for your specific application to avoid electrical hazards.

What Are Motor Starters? (basic introduction to starters), Three Phase Motor Starters: Types & Uses, Square D Motor Starters: Models & Uses

3 thoughts on “Motor Starters vs. Contactors: How They Differ & Work Together”