Regardless of whether you’re designing a robot, building a 3D printer, or developing an optimized CNC machine, motor selection is crucial. One such reliable solution is the NEMA stepper motor. This piece will help you learn the fundamentals of NEMA motors, their sizes, general applications, and how to choose the best one for your specific use case. Let’s start!

What Is a NEMA Stepper Motor?

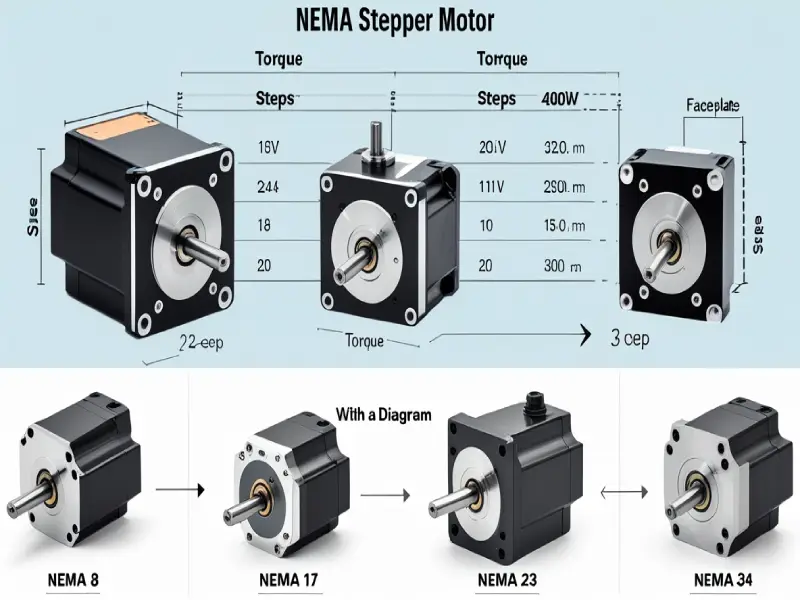

A NEMA stepper motor is an electric motor that travels in discrete steps and is ideal for applications where there is a need for precise movement. The “NEMA” refers to the National Electrical Manufacturers Association standard which specifies the motor size by the faceplate size. For instance, a NEMA 17 motor has a faceplate that is 1.7 x 1.7 inches. This standardized size allows motors of different manufacturers to share the same mounting points and gears, which makes them universal for various applications.

Key Features of NEMA Stepper Motors

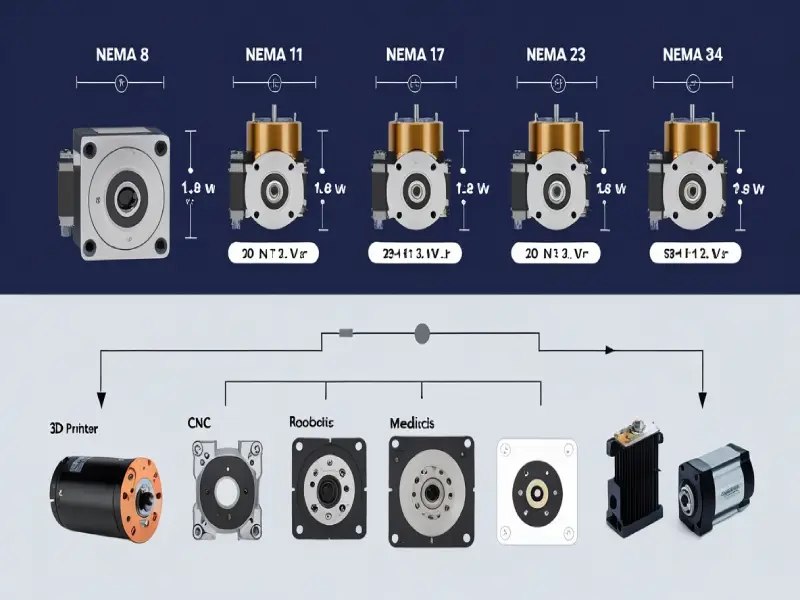

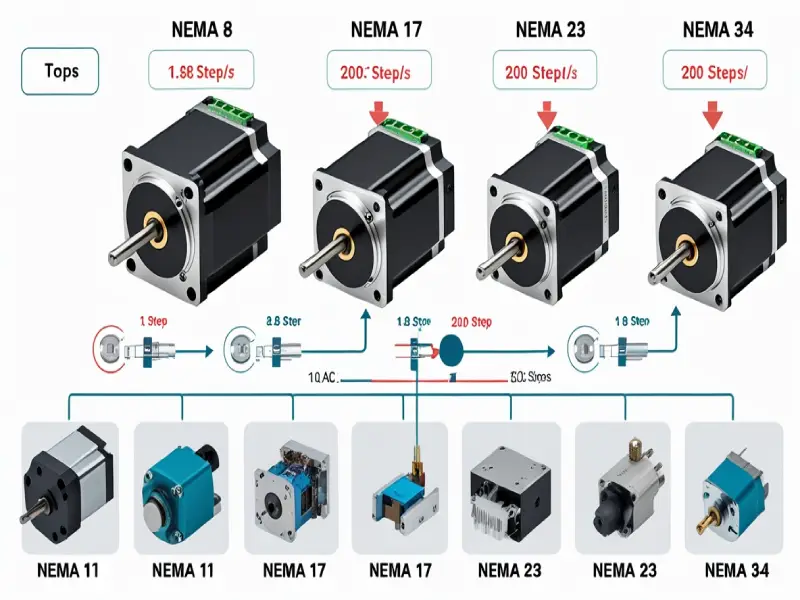

- Standard Sizes: NEMA 8, 11, 17, 23, and 34 are the standard sizes.

- Accuracy Control: These motors move in fixed steps (e.g., 200 steps for a complete rotation).

High Torque: Can handle heavy-duty operations like CNC milling and robotics.

NEMA Stepper Motor Sizes Explained: Which One Do You Need?

Understanding NEMA motor sizes is important when selecting the right motor for your project. Here’s a quick rundown of the most popular NEMA stepper motor sizes and the applications for which you should use them:

| NEMA Size | Faceplate (inches) | Typical Torque | Best For |

| NEMA 8 | 0.8 x 0.8 | 0.1 Nm | Small robots, cameras |

| NEMA 11 | 1.1 x 1.1 | 0.3 Nm | DIY clocks, lab equipment |

| NEMA 17 | 1.7 x 1.7 | 0.5–1.2 Nm | 3D printers, conveyor belts |

| NEMA 23 | 2.3 x 2.3 | 1.2–3.0 Nm | CNC machines, large robots |

| NEMA 34 | 3.4 x 3.4 | 4.0–15 Nm | Industrial machinery |

Why Size Matters:

- Smaller motors (NEMA 8–17) are space-efficient and power-efficient, perfect for tight spaces and light-duty applications.

- Larger motors (NEMA 23–34) are ideal for heavy-duty applications but use more power and occupy more space.

How Do NEMA Stepper Motors Work?

Think of a stepper motor as a dancer moving to a beat. Here’s how it works:

- Electrical Pulses: You send electrical pulses to the motor’s coils via a driver like A4988 stepper motor driver.

- Magnetic Rotation: Each pulse causes the rotor to rotate by a fixed angle (e.g., 1.8° per step for 200 steps/rev).

- Precision Control: The motor counts steps internally—no need for sensors. The more pulses, the smoother the motion.

Real-World Example:

A NEMA 17 motor is commonly used in 3D printers (e.g., Creality Ender 3). It moves the print head precisely, layer by layer, ensuring that each print is perfect.

Top Uses for NEMA Stepper Motors

These motors are essential for applications that require precise movement. Here are the most common uses:

1. 3D Printers

- NEMA 17 motors control the X/Y axes and extruder to ensure precise movement during printing.

2. CNC Machines

- NEMA 23 motors are commonly used to drive the cutting tools through metal or wood, offering strong torque for heavy-duty tasks.

3. Robotics

- NEMA 11-17 motors power robotic arms, enabling precise movements in industries like manufacturing and healthcare.

4. Medical Devices

- NEMA 8 motors are used in applications such as adjusting syringe pumps or MRI beds, where space is tight, and precision is critical.

Pro Tip: Pairing a NEMA stepper motor with a microstepping driver (such as the DRV8825) can reduce noise and improve movement smoothness, especially in sensitive applications.

How to Choose the Right NEMA Stepper Motor for Your Project

Choosing the right motor depends on three primary factors:

1. Torque Needs

- Low Torque (0.1–0.5 Nm): NEMA 8-11 motors are great for small applications like camera sliders.

- Medium Torque (0.5–3 Nm): NEMA 17-23 motors are ideal for 3D printers and CNC machines.

- High Torque (3+ Nm): NEMA 34 motors are needed for industrial applications like drills and heavy machinery.

2. Voltage & Current

Make sure to match your driver’s specs with the motor’s voltage and current ratings. For instance, most NEMA 17 motors operate on a 12V power supply.

3. Mounting Space

Make sure the motor fits within the designated space for your project. For example, NEMA 23 may be too large for a mini robot, but perfect for industrial machinery.

Pro Tip: Need speed and precision? Pair a NEMA motor with a micro stepping driver for silky-smooth motion.

How to Choose the Right NEMA Motor

Picking the perfect motor depends on three factors:

- Torque Needs:

- Low torque (0.1–0.5 Nm): NEMA 8-11 (e.g., camera sliders).

- Medium torque (0.5–3 Nm): NEMA 17-23 (e.g., 3D printers).

- High torque (3+ Nm): NEMA 34 (e.g., industrial drills).

- Voltage & Current:

- Match your driver’s specs. A 12V power supply works for most NEMA 17 motors.

- Mounting Space:

- Measure your project’s frame. NEMA 23 won’t fit a mini robot!

Popular NEMA Stepper Motors: Trusted Models for Every Need

Here are some popular NEMA stepper motors you can trust for different tasks:

- NEMA 17 (Creality 42-40): The go-to for 3D printers. Torque: 0.48 Nm, 1.5A.

- NEMA 23 (STEPPERONLINE 23HS30-3004S): Ideal for CNC machines. Torque: 3.0 Nm, 3.0A.

- NEMA 8 (Moons Industries 08HSS10-0704S): Small but powerful. Torque: 0.07 Nm, 0.4A.

Where to Buy:

You can find a wide selection of NEMA stepper motors on platforms like Amazon, StepperOnline, and specialized motor suppliers.

Controlling Your NEMA Motor

To control your NEMA stepper motor, you’ll need:

- Driver Board: Such as the A4988 or DRV8825.

- Controller: An Arduino or Raspberry Pi to send control signals.

Pros & Cons of NEMA Stepper Motors

Pros:

✅ Standardized sizes make it easy to replace or upgrade motors.

✅ Strong torque output relative to their size.

✅ No feedback loop required—works in open-loop control.

Cons:

❌ Can overheat if operated beyond their capacity.

❌ High-speed operation can be noisy (use microstepping to mitigate noise).

Conclusion

NEMA stepper motors are an essential instrument for precision applications, from household projects to heavy industry equipment. Familiarity with the NEMA motor sizes, selection of the correct torque, and the combination of the motor with the correct driver and controller will provide you with smooth and accurate performance for your application

Got questions? Check out the FAQs below or explore our guide on Micro Stepper Motors next!

FAQs

“NEMA” stands for the National Electrical Manufacturers Association, which standardizes motor sizes.

No, NEMA 23 is larger and offers higher torque than NEMA 17.

NEMA 17 is suitable for small CNC routers, but for metal cutting, a NEMA 23 or larger motor is recommended.

Yes! You can use a stepper motor driver board like the TB6600 with Python to control NEMA motors on a Raspberry Pi

Consider adding a heatsink, reducing the load, or upgrading to a motor with a larger size.

Ready to start using NEMA stepper motors for your next project? Check out our wiring guide for NEMA 17 motors or browse our top-rated NEMA motors for 3D printing and CNC machines