Hi there, automation enthusiasts! Whether you are a beginner who is just entering the realm of technology or a veteran with several years of experience, chances are you’ve dealt with sensors before. These tiny little things are usually the behind-the-scenes players of most systems we use, working tirelessly and collecting information as they make the necessary adjustments. One of the sensors you might be curious about is the O2 Sensor Bank 1. Today, let’s break down what it is, why it matters, and how it relates to the fascinating world of automation.

What is an O2 Sensor?

Imagine you’re in a car, cruising down the road, and your engine’s humming smoothly. But how does the engine know exactly how much fuel and air to use? This is where the O2 sensor (oxygen sensor) comes into play. It’s like a tiny detective in the exhaust system, constantly sniffing out the amount of oxygen in the exhaust gases.

The O2 sensor relays this vital information to the car’s “brain”—the Engine Control Unit (ECU). The ECU then employs this information to adjust the air-to-fuel ratio in real-time. Too oxygen-rich? The ECU injects more fuel. Not sufficient oxygen? It cuts back.

Think of the O2 sensor as a thermostat for your engine. A thermostat will regulate the heat when it is cold in a room, and the O2 sensor will regulate the fuel mixture so that the engine can keep going at the maximum level.

Breaking down Bank 1

Now, let’s talk about Bank 1. In later models, especially those with more than one bank of cylinders (like V6 or V8 engines), the engine is divided into two halves, known as “banks.” Bank 1 is the side that houses cylinder #1. In a V6 engine, Bank 1 could be on the left bank, and Bank 2 on the right bank.

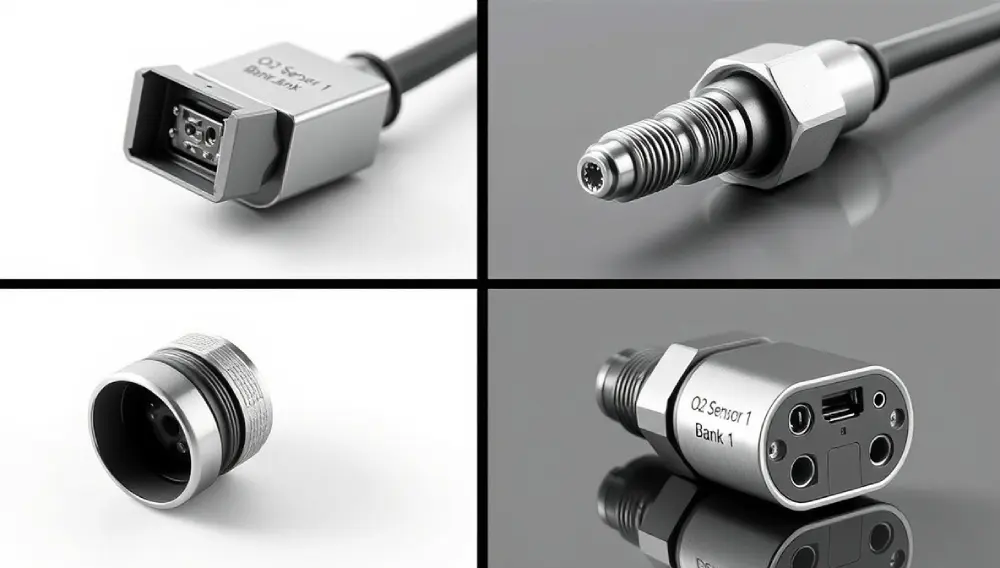

So when we say O2 sensor bank 1, we’re talking about the oxygen sensor on Bank 1’s exhaust pipe. Most cars typically have two O2 sensors per bank: an upstream (before the catalytic converter) and a downstream (after the converter) O2 sensor. The upstream sensor (the Bank 1 sensor) is quite crucial since it directly affects fuel management and engine performance.

Why Automation Enthusiasts Should Care

At its most basic, automation consists of systems that change based on feedback—like the O2 sensor bank 1. Sensors allow machines to make decisions from information they sense, and the O2 sensor is a good illustration of this. Here’s why it should alarm automation lovers like you:

- 1. Real-Time Adjustments

- In automation, we are often dealing with systems that automatically change based on information. The O2 sensor bank 1 is no exception.

- The ECU receives the reading from the oxygen sensor and adjusts the air-fuel mixture every 15 milliseconds!

- That is a quick response, similar to the way an automated system will modify its procedures in real-time.

- 2. Efficiency

- The O2 sensor has a significant function in achieving optimal engine efficiency.

- As algorithms in computer-controlled factories optimize energy consumption, so also a healthy O2 sensor will mean that your vehicle consumes the appropriate amount of fuel and air, producing improved fuel efficiency and reduced emissions.

- 3. Problem-Solving

- One of the most exciting parts of automation is troubleshooting. Sensors are critical to detecting problems, and fixing them is like debugging code.

- If the O2 sensor bank 1 is malfunctioning, the air-fuel mix in your engine is off, and you need to troubleshoot.

- From machinery, and robots, to cars, finding the right data source (or sensor) is the key to solving the problem.

Common Problems with O2 Sensor Bank 1 (And How to Identify Them)

Sensors are not immortal, and occasionally they do fail. Below are some warning signs that could suggest something is amiss with your O2 sensor bank 1:

- ???? Check Engine Light

- If your check engine light comes on in your vehicle, it can be caused by a bad O2 sensor bank 1. Scan the codes with an OBD2 scanner. Some popular codes related to the O2 sensor bank 1 are P0130, P0135, and more. Keeping a scanner with you is a great investment for any automation enthusiast because it lets you know what’s going wrong.

- ⛽ Bad Gas Mileage

- One of the first signs that the O2 sensor bank 1 may be on the way out is an unexpected loss of fuel efficiency. When the sensor sends false information, the ECU may alter the fuel mixture incorrectly, causing your car to use more gas than it should.

- ????️ Failed Emissions Test

- If your car fails an emissions test, then the bank 1 O2 sensor could be the culprit. This sensor plays a role in keeping emissions much lower and thus making the engine run properly. A lagging sensor would result in more pollution, and this is the most common cause of emissions test failure.

- ???? Rough Idling

- A bad O2 sensor bank 1 will cause your engine to run poorly. If the air-fuel mixture is incorrect, the engine will not idle smoothly. You might feel the engine stall, sputter, or run roughly while idling at a red light.

Tips to Keep Your O2 Sensor Bank 1 Happy

Just like any other component on your car, the O2 sensor bank 1 also needs some TLC to live longer. Here are a few tips to keep it in tip-top shape:

- 1. Use Quality Fuel

- Cheap or low-quality fuel clogs the O2 sensor, which can cause premature failure. Always use high-quality fuel to keep the sensor in good working condition.

- 2. Fix Problems Fast

- Ignoring issues like engine misfires or poor engine performance can cause undue stress on the O2. If something doesn’t feel right, don’t wait.

- 3. Check Regularly

- When having routine maintenance like an oil change or an emissions check, have a mechanic scan the O2 sensor. Better to find out about looming problems before they become problems.

- 4. Replace When Needed

- On average, an O2 sensor would last 60,000 to 100,000 miles. But it depends on your driving style and the type of car. Don’t play with fate—if your O2 sensor bank 1 is already worn out, replace it before it causes more serious issues.

A Personal Automation Story

I’ll give you an example. A number of years back, I was working on a small robot. It was veering off to the left, even though it had been programmed to move straight. After some troubleshooting, I discovered that a dirty sensor was providing it with false data. This reminded me of when my O2 sensor bank 1 in my vehicle malfunctioned. I’d been neglecting the check engine light until I noticed my gas mileage plummeting through the floor.

Replacing the sensor fixed the issue for my car and my robot as well! This was a great lesson in how critical sensors are. Whether debugging a robot or doing car diagnostics, clean data is the key to smooth performance.

Wrapping Up

O2 sensor bank 1 can be a small device of your vehicle, but the role it plays in the performance and efficiency of the engine is immense. For automation enthusiasts such as ourselves, it’s the perfect example of how feedback works in systems. The sensor adjusts the engine fuel mixture in real time, for smooth operation and lower emissions.

As an automation enthusiast, it’s a useful skill to know and take care of these sensors. You can apply these principles to all kinds of applications ranging from car diagnostics to robot systems. So the next time you see that dreaded check engine light, be like an automation guru: troubleshoot, test, and tune.

2 thoughts on “O2 Sensor Bank 1 An Easy Guide for Automation”