Whether you’re an engineer, technician, or hobbyist, Programmable Logic Controllers (PLCs) are essential for industrial automation. This guide explains what PLCs are, how they work, top models, and how to choose the right one—all in simple terms.

Let’s dive in!

What Is a PLC ?

A PLC is a rugged industrial computer that automates machinery and processes. It reads inputs (like sensors), processes them using programmed logic, and controls outputs (like motors, valves, or lights).

Why Use a PLC Instead of a Regular Computer?

✔ Durability – Built for harsh environments (dust, moisture, vibrations)

✔ Real-time control – Responds instantly to changes

✔ Reliability – Runs 24/7 without crashing

✔ Flexibility – Reprogrammable for different tasks

Where Are PLCs Used?

- Manufacturing (assembly lines, robotic arms)

- Energy (power plants, oil refineries)

- Food & Beverage (packaging, bottling)

- Automotive (car production, welding)

- Building Automation (HVAC, elevators)

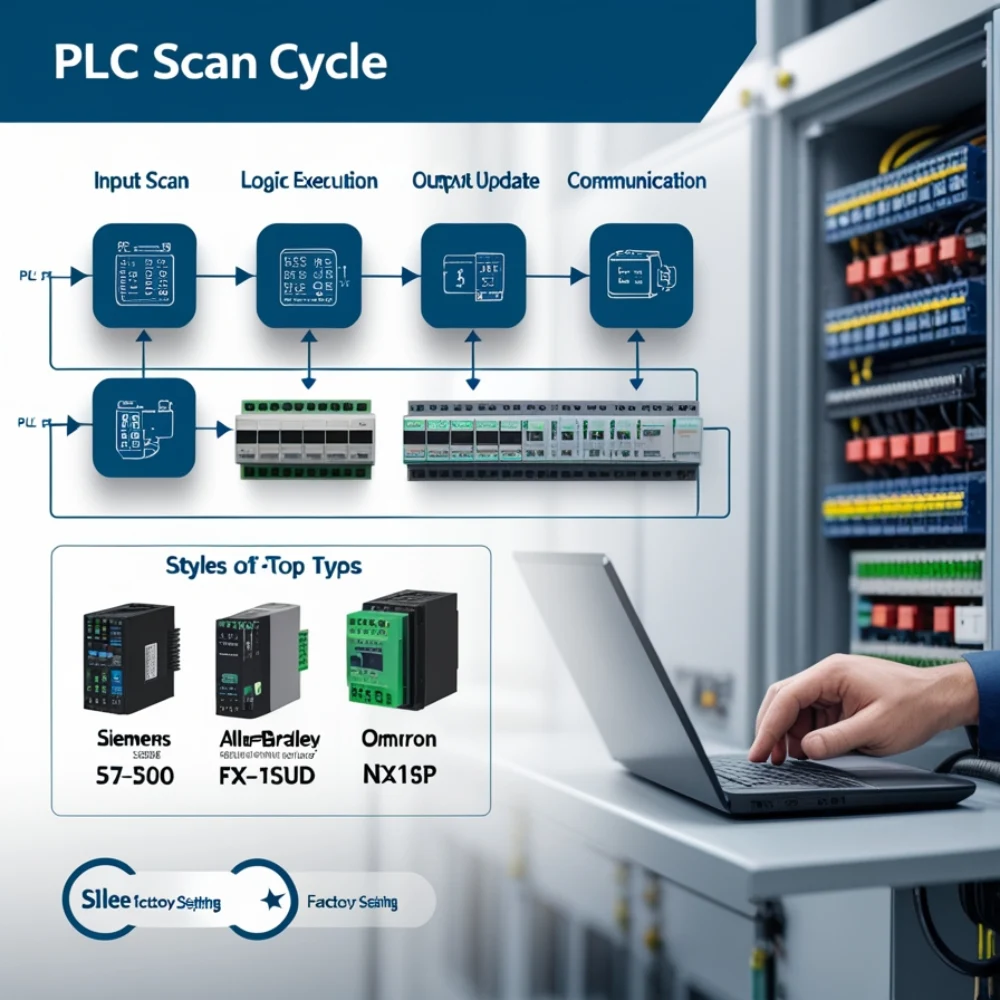

How Does a PLC Work? (Simple Breakdown)

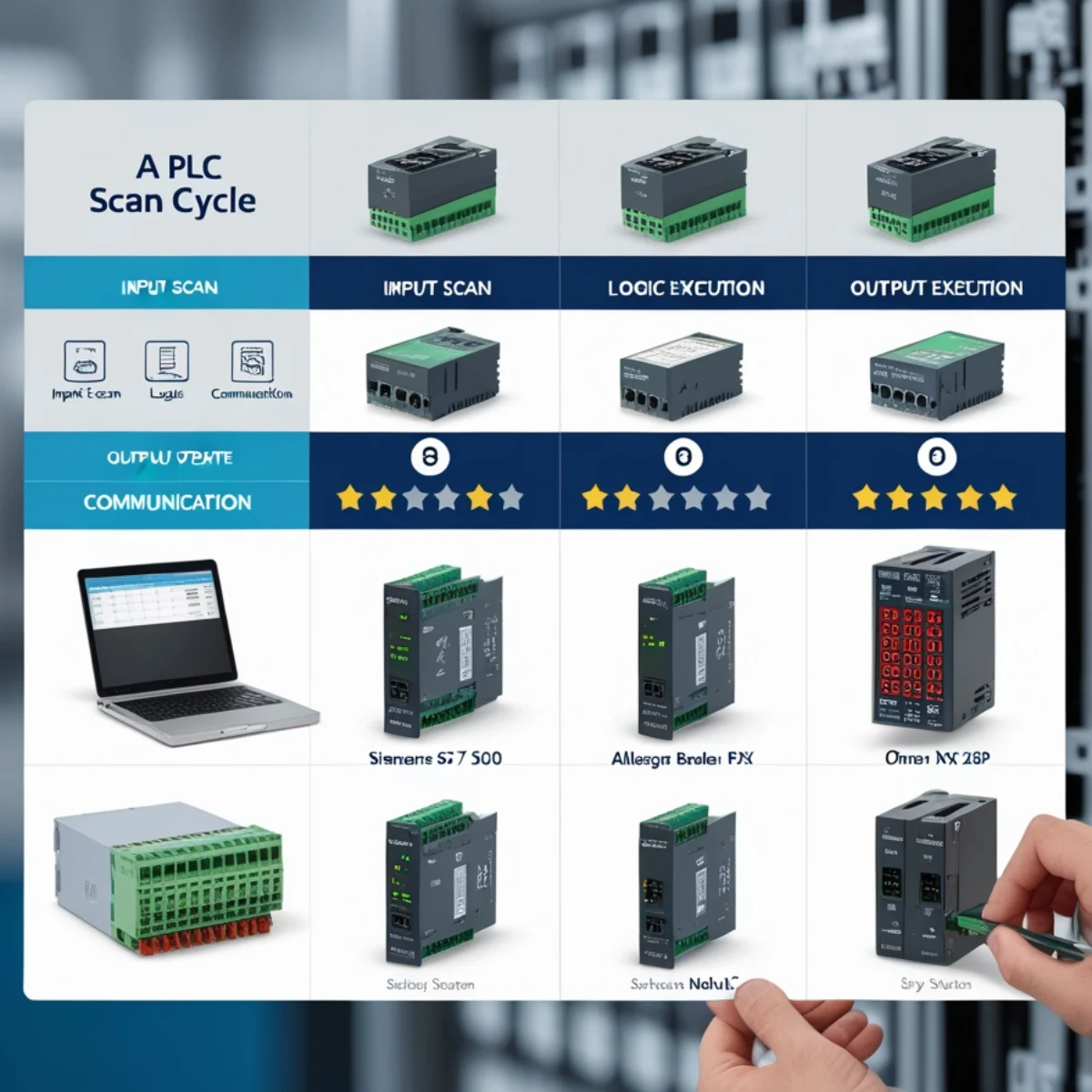

PLCs follow a continuous scan cycle:

- Input Scan – Checks sensors (e.g., temperature, pressure).

- Logic Execution – Runs programmed instructions (ladder logic, structured text).

- Output Update – Activates devices (motors, pumps, alarms).

- Communication & Diagnostics – Sends data to SCADA/HMI systems.

This happens hundreds of times per second, ensuring precise control.

Types of PLCs (Which One Do You Need?)

| Type | Best For | Example |

|---|---|---|

| Compact PLC | Small machines, basic automation | Siemens S7-1200 |

| Modular PLC | Scalable systems, large factories | Allen-Bradley ControlLogix |

| Rack-mounted PLC | High-speed, heavy-duty automation | Mitsubishi Q Series |

| Soft PLC | PC-based control (virtualized) | Beckhoff TwinCAT |

Top 5 PLCs in 2024 (Pros, Cons & Best Use Cases)

1. Siemens SIMATIC S7-1500

✅ Pros:

- Blazing-fast processing

- Advanced diagnostics & cybersecurity

- Works with TIA Portal (industry-standard software)

❌ Cons:

- Expensive

- Steeper learning curve

Best for: Large-scale automation, smart factories

2. Allen-Bradley CompactLogix 5380

✅ Pros:

- Rock-solid reliability

- Seamless integration with FactoryTalk

- Great for motion control

❌ Cons:

- High cost

- Limited third-party compatibility

Best for: Automotive, pharmaceutical industries

3. Mitsubishi FX5U

✅ Pros:

- Affordable & compact

- Supports multiple programming languages

- High-speed counters

❌ Cons:

- Software (GX Works3) isn’t as intuitive

Best for: Small to medium automation projects

4. Omron NX1P

✅ Pros:

- Built-in Ethernet & safety features

- Easy to program (Sysmac Studio)

- Great for IoT applications

❌ Cons:

- Limited expansion modules

Best for: Packaging, material handling

5. Schneider Electric Modicon M580

✅ Pros:

- Top-tier cybersecurity

- EcoStruxure compatibility (IIoT-ready)

- Energy-efficient

❌ Cons:

- Complex setup for beginners

Best for: Water treatment, power distribution

PLC Buying Guide

1. I/O Requirements

- Count your sensors (inputs) and actuators (outputs).

- Choose a PLC with 20-30% extra I/O for future upgrades.

2. Processing Power

- Basic tasks (e.g., conveyor control) → Omron CP1E

- High-speed precision (e.g., robotics) → Siemens S7-1500

3. Communication Protocols

Ensure your PLC supports:

- Ethernet/IP (Allen-Bradley)

- Profibus (Siemens)

- Modbus RTU/TCP (universal)

4. Programming Software

- Siemens → TIA Portal

- Allen-Bradley → Studio 5000

- Mitsubishi → GX Works3

5. Environmental Ratings

- IP20 (basic protection)

- IP67 (dustproof, waterproof)

6. Budget

- <$500 → Basic trainers (Click PLC)

- 500−500−2000 → Mid-range (Mitsubishi FX5U)

- >$3000 → Industrial-grade (ControlLogix)

My Hands-On Experience With PLCs

I’ve programmed Siemens, Allen-Bradley, and Omron PLCs in automotive plants. Here’s what I learned:

- Siemens S7-1200 was the easiest to learn (great for beginners).

- Allen-Bradley ControlLogix was the most robust (perfect for heavy industry).

- Omron NX1P had the best IoT integration.

Pro Tip: If you’re new to PLCs, start with a simulator (like PLCSIM for Siemens) before working on real hardware.

FAQs About PLCs

❌ No—PLCs are industrial-grade; Raspberry Pi isn’t rugged enough for factories.

1.Siemens S7-1200 (user-friendly software)

2.Click PLC (simple ladder logic)

✅ 10-20 years with proper maintenance.

✔ Yes! It’s the #1 PLC programming language (especially in the US).

1. More IoT integration

2. AI-driven predictive maintenance

3. Cybersecurity enhancements

Final Recommendation

- Beginners: Start with Omron CP1E or Siemens S7-1200.

- Professionals: Go for Allen-Bradley ControlLogix or Siemens S7-1500.

Need help choosing? Drop a comment below!

More Blog: programmable logic controller

2 thoughts on “Programmable Logic Controllers (PLCs) |Rates |Guide| Tips | Maintenance | FAQ |”