Introduction

Imagine a world where robots perform surgery with unerring precision, drones navigate stormy skies without faltering, and factories hum with machines that never miss a beat. This isn’t a distant future—it’s the reality powered by servo motors, the unsung heroes of modern automation. Whether you’re a student building your first robot, an engineer optimizing industrial machinery, or a hobbyist crafting a smart home gadget, understanding servo motors is your gateway to precision control.

By the end of this guide, you’ll:

- Master the mechanics of servo motors and their closed-loop magic.

- Compare types like BLDC, AC, and micro servo motors for your needs.

- Avoid pitfalls like overheating or misalignment with pro tips.

- Unlock real-world applications from aerospace to DIY projects.

Let’s dive deep—no PhD required!

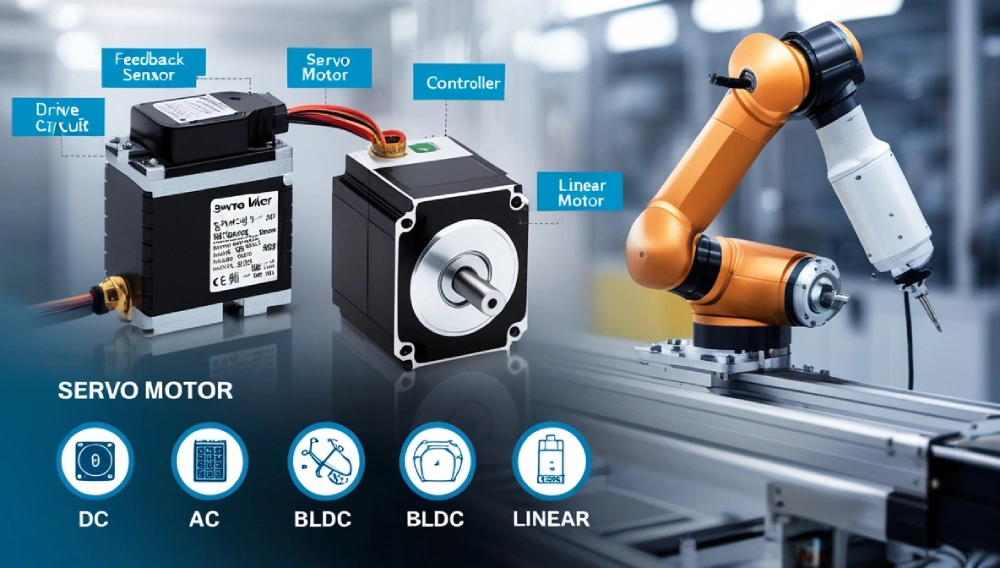

What is a Servo Motor?

A servo motor is a self-aware powerhouse. Unlike ordinary motors that spin blindly, servo motors use real-time feedback to adjust their position, speed, or torque. Think of it as a GPS-guided engine: it knows exactly where it is, where it needs to go, and how to course-correct instantly.

Core Components:

- Motor: The muscle (DC, AC, or brushless).

- Controller: The brain sending commands. e.g. Arduino

- Feedback Sensor: The eyes (encoder, potentiometer) tracking performance.

- Drive Circuit: Amplifies signals to power the motor.

Real-World Analogy:

It’s like a self-driving car that adjusts steering, acceleration, and braking to stay perfectly in lane—no human intervention needed!

How Servo Motors Work: The Science Made Simple

- Command Input: You set a target ( “Rotate 90 degrees”).

- Motion Starts: The motor begins moving toward the goal.

- Feedback Loop: Sensors monitor progress and report deviations.

- Adjustment: The controller tweaks voltage, current, or pulse width to hit the target.

Why This Matters:

Servo motors eliminate guesswork. For example, in a 3D printer, they ensure layers align perfectly—no gaps or misprints.

Types of Servo Motors: Which One Fits Your Project?

1. DC Servo Motors

- Best For: Budget-friendly DIY projects, small robotics.

- Example: TowerPro SG90 ($5, Arduino-compatible).

- Pros: Affordable, lightweight, easy to control.

- Cons: Limited torque, shorter lifespan under heavy use.

Read more about DC Servo Motors!

Pro Tip: Love tinkering? Start with a micro servo motor (like MG90S) for under $10.

2. AC Servo Motors

- Best For: Industrial machinery (CNC, conveyor belts).

- Example: Yaskawa SGM7G (handles 1,000+ hours of continuous operation).

- Pros: High torque, durable, ideal for heavy loads.

- Cons: Expensive, requires complex controllers.

3. BLDC Servo Motors (Brushless)

- Best For: High-speed, low-maintenance tasks (drones, EVs).

- Example: T-Motor MN5208 (used in racing drones).

- Pros: Energy-efficient, long lifespan, minimal heat.

- Cons: Higher cost, needs specialized drivers.

Read More about BLDC Servo Motors!

4. Linear Servo Motors

- Best For: Straight-line motion (3D printers, automated doors).

- Example: Hiwin LSA Series.

- Pros: No gears = zero backlash, ultra-smooth motion.

- Cons: Limited to linear paths, higher cost.

5. Micro Servo Motors

- Best For: Hobby projects (RC cars, camera gimbals).

- Example: MG90S (metal gears for durability).

- Pros: Compact, affordable, easy to integrate.

- Cons: Limited torque (5-10 kg/cm).

Read More about Micro Servo Motors!

Servo Motors vs. Stepper Motors: The Ultimate Face-Off

| Factor | Servo Motors | Stepper Motors |

| Control System | Closed-loop (self-correcting) | Open-loop (no feedback) |

| Precision | ±0.1° accuracy | ±1.5° (prone to missed steps) |

| Speed | Up to 5,000 RPM | Up to 1,200 RPM |

| Torque at Speed | Maintains torque at high speeds | Torque drops as speed increases |

| Cost | 20−20−500+ | 5−5−200 |

| Best For | Robotics, CNC, aerospace | 3D printers, basic automation |

Key Takeaway:

- Choose Servo Motors for precision tasks (surgical robots).

- Choose Stepper Motors for cost-sensitive, low-speed projects (conveyor belts).

Still Confused? Dive deeper: Servo vs. Stepper Motors: Which Wins for Your Project?

Applications of Servo Motors: From Factories to Your Living Room

1. Industrial Automation

- CNC Machines: AC servo motors cut metal with 0.001mm precision.

- Packaging Lines: BLDC motors fill, seal, and label 100+ products/minute.

- Textile Machinery: M92 Juki servo motors stitch denim 2x faster than clutch motors.

2. Robotics

- Robotic Arms: Six-axis arms use 6+ servo motors for welding, painting, and assembly.

- Humanoid Robots: Micro servo motors mimic human joint movements.

3. Aerospace

- Satellites: BLDC motors adjust solar panels to maximize energy capture.

- Drones: Lightweight servos stabilize cameras and adjust propeller pitch.

4. Consumer Tech

- Camera Gimbals: Micro servos keep footage steady while hiking or biking.

- Smart Homes: Linear servos automate blinds, locks, and pet feeders.

5. Automotive

- Electric Vehicles: BLDC motors control throttle response and regenerative braking.

- Advanced Driver-Assistance Systems (ADAS): Servos adjust steering and braking in real time.

How to Choose the Right Servo Motor: A 7-Step Guide

1. Define Your Application

- Precision Tasks ( robotic surgery): Closed-loop BLDC motors.

- Heavy Loads (CNC machines): High-torque AC servo motors.

- Hobby Projects (Arduino robots): Micro DC servo motors.

Check Out

2. Calculate Torque & Speed Requirements

- Torque Formula: Torque (Nm)=9.5488Force (N)×Radius (m)

- Example: A robotic arm lifting 5kg at 0.1m radius needs ~0.5 Nm torque.

3. Match Power Supply

- DC Motors: 5V-12V (Arduino-friendly).

- AC Motors: 110V-240V (industrial setups).

4. Check Feedback Resolution

- Encoders: 12-bit (4,096 steps) for high precision.

- Potentiometers: 10-bit (1,024 steps) for basic tasks.

5. Environment-Proofing

- IP Ratings: IP65 for dust/water resistance.

- Temperature: -20°C to 80°C for most models.

6. Budget Considerations

- Hobbyists:

- 5−50 (e.g., SG90, MG996R).

- Professionals:

- 200−1,000+ (e.g., Yaskawa, Allen-Bradley).

7. Brand & Support

- Top Brands:

- Faulhaber: Precision micro motors.

- Yaskawa: Industrial-grade AC servos.

- T-Motor: BLDC motors for drones.

Installation & Maintenance: Pro Tips for Peak Performance

Step-by-Step Installation Guide

- Mounting:

- Use anti-vibration brackets to reduce noise.

- Alhaftach motors parallel to the load axis to prevent binding.

- Wiring:

- Power: Red (+) to power supply, Black (-) to ground.

- Signal: Orange/Yellow to PWM pins (Arduino, Raspberry Pi).

- Calibration:

- Use software like RoboDK or Arduino IDE to set zero position.

- Testing:

- Run at 50% load initially to check for overheating or jitter.

Maintenance Checklist

- Daily: Listen for unusual noises (grinding = worn gears).

- Monthly: Clean vents with compressed air.

- Annually: Replace grease in gearboxes (if applicable).

Troubleshooting Common Issues

| Problem | Cause | Fix |

| Motor Jitters | Loose wiring | Secure connections |

| Overheating | Overloading | Reduce load or add cooling fan |

| No Movement | Dead power supply | Test with multimeter |

| Inaccurate Stops | Faulty encoder | Recalibrate or replace sensor |

FAQs: Your Servo Motor Questions, Answered

No! Servo motors rely on controllers (Arduino, PLC) to send PWM signals.

For precision, yes! Servo motors self-correct; DC motors run open-loop.

5-10 years with proper maintenance. BLDC motors often outlast brushed types.

Most standard servos rotate 180°, but continuous rotation servos (Parallax) spin freely.

It’s “hunting” for position—recalibrate or reduce mechanical resistance.

The Future of Servo Motors: Trends to Watch

- AI Integration: Motors that learn and adapt to load changes.

- IoT Connectivity: Remote monitoring via apps ( diagnose issues from your phone).

- Eco Designs: Energy recovery systems that feed excess power back to the grid.

Conclusion: Ready to Harness Servo Power?

Servo motors are the quiet revolutionizers of automation, transforming industries and hobbies alike. Whether you’re retrofitting a sewing machine with an M92 Juki motor or building a Mars rover prototype with micro servos, the right choice ensures flawless performance.

Your Next Steps:

- Explore: Browse servo motors on ServoCity or Amazon.

- Learn: Master PWM control with our Arduino Servo Guide.

- Connect: Join forums like Reddit’s r/robotics for expert advice.

Read More,

Motor Drivers for Servo Motors,

Servo Motor vs Stepper Motor Comparison,

Servo Motors vs Regular Motors

About the Author:

John Carter is a robotics engineer with 12+ years of experience. She’s designed servo systems for NASA rovers and now runs a YouTube channel teaching DIY automation.

Loved This Guide? Share it with your colleagues, students, or maker community!

16 thoughts on “Servo Motors | Applications| Mastery and Where to Buy the Best”