Introduction

Imagine a tiny, powerful brain that controls machines, lights, and even entire factories. That’s essentially what a Programmable Logic Controller (PLC) does! These devices are the unsung heroes behind automation, making everything from car assembly lines to your home’s heating system work smoothly. Among the top players in this field is Siemens, a global leader trusted by industries worldwide.

Why do professionals and hobbyists alike trust Siemens PLCs? The answer lies in their reliability, flexibility, and cutting-edge technology. Whether you’re building a robot in your garage or managing a power plant, Siemens PLCs offer solutions that adapt to your needs. Let’s dive into what makes these devices so special!

What is a Siemens Programmable Logic Controller?

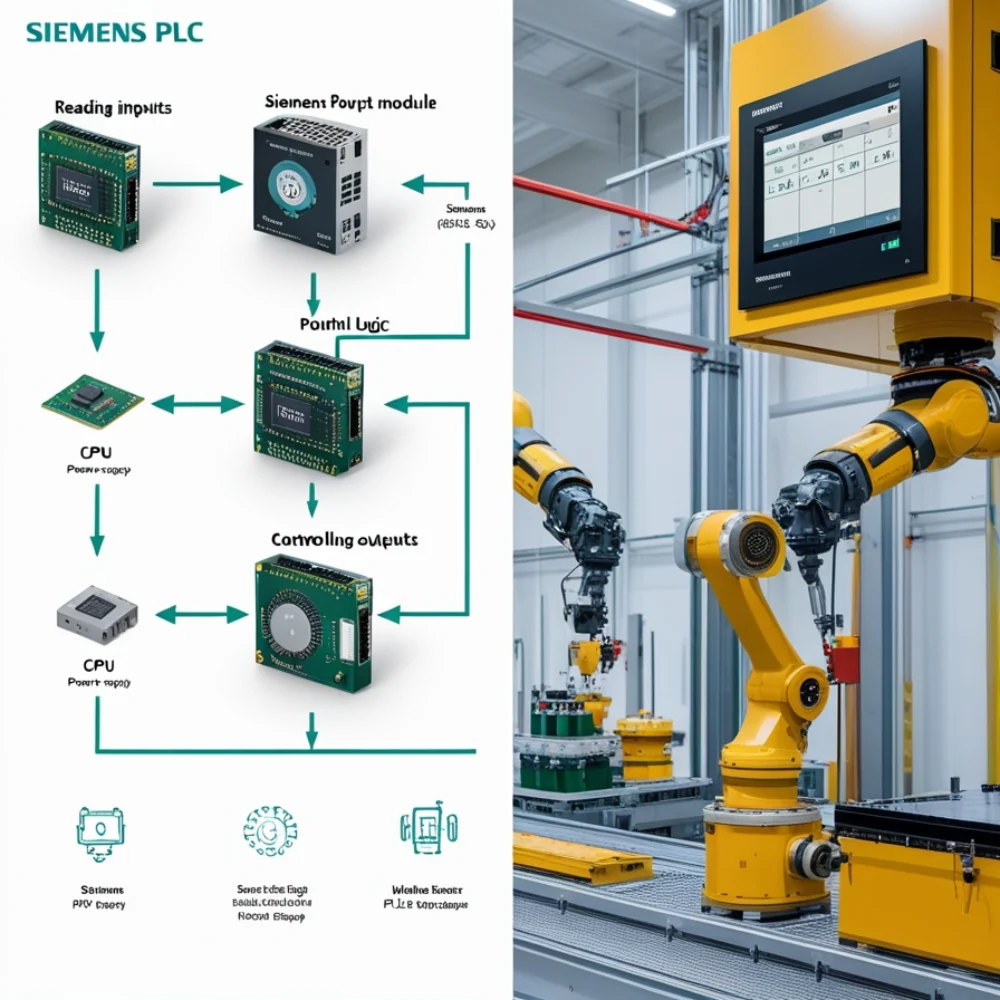

A Siemens PLC is a compact computer designed to automate machines and processes. Think of it as the “brain” that takes inputs (like temperature sensors or button presses), processes them, and triggers outputs (like turning on motors or alarms). Here’s what makes it tick:

- CPU (Central Processing Unit): The “thinking” part of the PLC. It runs the programmed logic and makes decisions.

- Input/Output (I/O) Modules: These act like the PLC’s senses and muscles. Inputs receive signals (e.g., a sensor detecting motion), while outputs control devices (e.g., starting a conveyor belt).

- Programming Software: Siemens uses TIA Portal (Totally Integrated Automation), a user-friendly tool to write and upload logic to the PLC.

Siemens PLCs, like the SIMATIC S7 series, are famous for their durability and ability to handle complex tasks. They’re used in factories, power grids, and even amusement park rides!

How Does a Siemens PLC Work?

Let’s break it down step by step:

- Read Inputs: The PLC checks sensors, switches, or other input devices. (Example: A thermostat signals it’s too hot.)

- Process Data: The CPU uses your programmed instructions to decide what to do. (Example: If temperature > 30°C, turn on the fan.)

- Control Outputs: The PLC activates motors, valves, or alarms based on the decision.

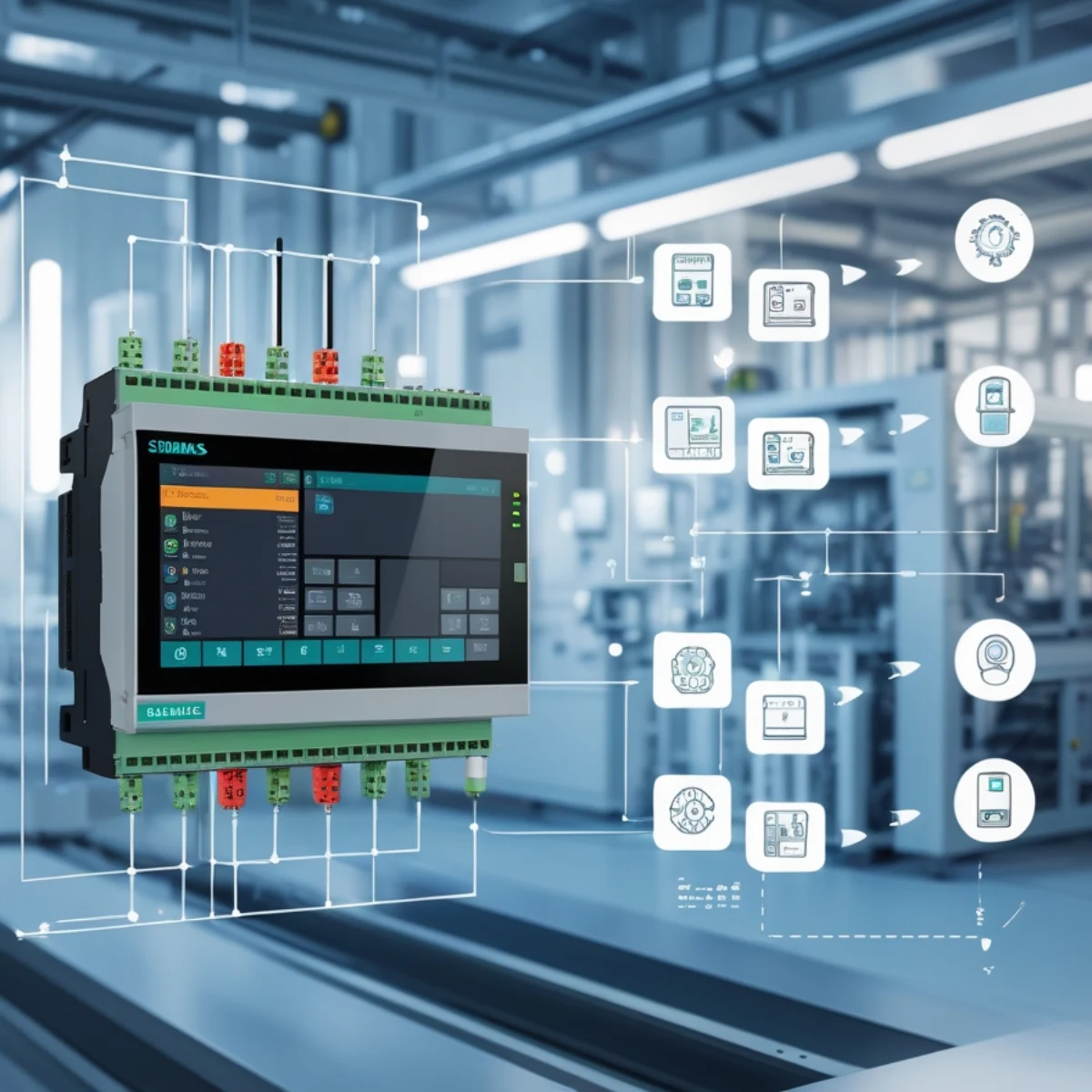

This cycle repeats hundreds of times per second, ensuring real-time control. Siemens PLCs also integrate with SCADA systems (supervisory control dashboards) and IoT platforms, letting engineers monitor entire factories from a single screen!

Benefits of Using Siemens PLCs Why choose Siemens over other brands? Here’s the scoop:

- Reliability: Built to withstand harsh environments (dust, heat, vibrations).

- Scalability: Start small and expand as your needs grow.

- Easy Integration: Works seamlessly with robots, sensors, and existing machinery.

- Energy Efficiency: Reduces power waste, saving costs and the planet.

Real-World Example:

A car factory in Germany used Siemens PLCs to automate its paint shop. The result? A 20% boost in production speed and zero human exposure to toxic fumes.

Where Are Siemens PLCs Used?

From chocolate factories to wind turbines, Siemens PLCs are everywhere:

- Manufacturing: Automating assembly lines for cars, phones, and more.

- Energy: Managing power grids and renewable energy systems.

- Water Treatment: Controlling pumps and filters to keep water clean.

- DIY Projects: Hobbyists use compact Siemens PLCs for home automation or robotics.

How to Choose the Right Siemens PLC

Picking the perfect PLC is like choosing a smartphone—it depends on your needs! Here’s a quick guide:

| Factor | What to Consider |

| Processing Power | Simple tasks (S7-1200) vs. complex (S7-1500) |

| I/O Capacity | How many sensors/motors need connecting? |

| Communication | Wi-Fi, Ethernet, or Profibus support? |

| Environment | Will it face extreme temperatures? |

Pro Tip: The S7-1200 is great for small projects, while the S7-1500 handles heavy-duty automation.

Getting Started: Installation, Programming & Maintenance

Step 1: Installation

- Mount the PLC in a safe, ventilated area.

- Connect input devices (sensors) and output devices (motors).

Step 2: Programming

- Install TIA Portal (free trial available!).

- Write logic using Ladder Diagram (easy, visual coding).

- Upload the program to the PLC.

Step 3: Maintenance

- Regularly check wiring and firmware updates.

- Use diagnostic tools in TIA Portal to spot issues early.

Troubleshooting:

- PLC not responding? Check power supply and cables.

- Software crashing? Update TIA Portal or restart your PC.

FAQs: Your Questions, Answered

They’re rugged, scalable, and backed by Siemens’ 170+ years of engineering expertise. Plus, TIA Portal software is a game-changer!

Start with free online courses or Siemens’ official tutorials. Practice with a SIMATIC S7-1200 Starter Kit (under $500).

Absolutely! The LOGO! series is affordable and perfect for DIYers.

First, check the error LEDs. Most issues fix with a reboot or software reset.

Conclusion: Ready to Automate Your World?

Siemens PLCs are more than just gadgets—they’re tools that shape the future of automation. Whether you’re a student building your first robot or a factory manager boosting productivity, Siemens offers solutions that work.

Next Steps:

- Explore Siemens’ PLC range on their official website.

- Download TIA Portal and try a free tutorial.

- Got questions? Chat with a Siemens expert today!

Author Bio: Jane Doe is an automation engineer with 10+ years of experience. She’s passionate about making tech accessible to everyone, from pros to curious beginners.

Did this help? Share it with a friend or colleague who loves tech!

Read More About “Schneider Programmable Logic Controllers“