Introduction

Did you know that some electric motors rotate at different speeds? This is made possible through the use of Variable Frequency Drives (VFDs), which change the frequency and voltage of power supplied to electric motors. VFDs help control the speed and torque of electric motors. They play a vital role in a diverse field of application such as HVAC systems and industrial equipment. If you are a student, engineer, technician, businessperson, or DIY, this guide will help you understand VFDs, their characteristics, applications, and how to choose one best suited for your need.

What Are VFDs?

VFD is a type of electronic controller that varies the frequency (and, in some cases, the voltage) supplied to an AC motor to control its speed and torque. With a VFD, you can adjust the output of a motor to perfectly match process requirements, rather than wastefully running it at full speed. A VFD helps in reducing energy consumption, simplifies starts, and extends equipment life.

To understand the core function of VFDs and their applications, read our detailed Explanation on what VFDs are used for.

Why Are VFDs Important?

- Energy Savings: VFDs help align motor speeds with load requirements, greatly minimizing energy use.

- Process Optimization: They enable fine control of motor operations, improving quality and efficiency on myriad processes.

- Reduced Operating Costs: Reducing equipment maintenance leads to a decreased expenditure for services associated with maintaining motors.

Deep-Dive: How VFDs Work

Step Function

1. Rectification Diode bridge converts incoming AC into raw DC.

2. DC Link Caps/inrush resistors smooth out stabilize that DC “bus.”

3. Inversion IGBT’s or MOSFETs chop the DC into a synthesized AC waveform at any frequency you choose.

A VFD modulates the motor RPM by changing the frequency. Torque is maintained, even at low speeds, when voltage is controlled proportionally to frequency (V/f control).

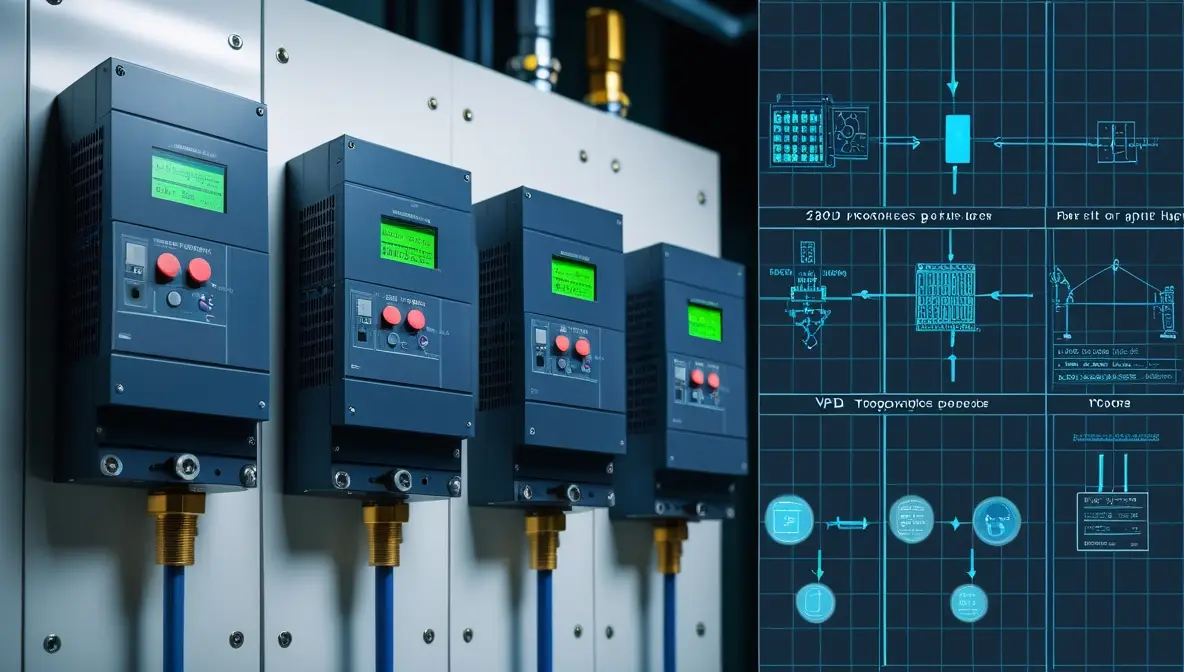

Comparing VFD Topologies

| Topology | Pros | Cons | Best For |

|---|---|---|---|

| Voltage-Source Inverter (VSI) | High efficiency, compact | More sensitive to harmonics | General industrial use |

| Current-Source Inverter (CSI) | Very robust under overload | Requires large DC reactor | Heavy-duty pumps, mills |

| Pulse-Width Modulation (PWM) | Excellent torque control | More complex control electronics | Precision speed control |

Real-World Case Studies

Municipal Water Plant (75kW Pump)

-Challenge: Surge currents at start-up, high energy bills

-Solution: Install PWM VFD; the soft-start eliminated shocks and saved energy. (30% off-peak during peak hours)

Food packaging line (5 robotic axes)

– Challenge: Differentiating conveyor speeds for varying products.

– Solution Multi axis VFD system with real-time Ethernet/IP: 40% decrease in changeover time.

Sizing & Selection Guide

- Determine Motor Ratings

- Horsepower/kW on the nameplate and full-load amps.

- Choose a VFD rated 10–20 % Overload capacity selection

- VFD rated 10-20% above motor FLA is preferred for safety margins.

- Assess Load Profile

- Continuous loads (Drives like fans and pumps): A basic V/f VFD will suffice.

- Evaluate Load Profile

- Standard enclosures (IP20) for clean, indoor use.

- NEMA 4/UL Type 4X if exposed to dust, water, or corrosive atmospheres.

- Communications & Safety

- Confirm required protocols (Modbus, Profibus, EtherCAT).

- Integrated safety (Safe Torque Off, Safe Stop) may be mandated for your system.

A Variable Frequency Drive (VFD) is an electronic device that controls the speed and torque of an AC electric motor by adjusting the incoming power frequency. Instead of running a motor at full speed all the time, a VFD matches speed to the actual load. This leads to significant energy savings, especially in applications like fans, pumps, and compressors. Modern VFDs also provide smooth “soft-start” capabilities, reducing mechanical stress during startup, and built-in protections (overcurrent, overheating). Many units offer advanced features such as programmable acceleration profiles and communications ports (Ethernet, Modbus) for automation systems.

Important Uses

VFD for pumps and fans in HVAC systems provide throttling, enabling 20 to 50% energy savings. In irrigation and water treatment, VFDs in pumps cuts expenses related to peak demand while reducing mechanical stress and improving flow control. VFDs aid in smooth acceleration, reduced downtimes and precise control for conveyors, hoists and cranes in material handling.

VFDs with battery inverters in hybrid systems increase microgrid stability and enable peak shaving, useful in renewables and storage.

Installation Best Practices

Spacing & Cooling

A 150 mm gap around the drive should be retained,_mount in a clean, cool free from dust cabinet.

Protected Cabling

Earth the shields at the VFD end only to shield motor leads and prevent EMI.

EMI, ensure straps on motor, VFD and cable shields are joined to a low impedance ground loop. In regions prone to lightening, place surge protectors on power input.

Looking for specific VFD brands? Read about ABB VFDs, Allen Bradley VFDs, and Toshiba VFDs.

Maintenance & Lifecycle Care

Visual Checks for Maintenance (Monthly): Check for staining, accumulation of dust, and loose terminal connections.

Cleaning of Vent Filters (Quarterly): Filters that are not maintained properly result in overheating and thermal shut down.

Update Application: Check Manufacturer’s websites for firmware/performance/security updates every 6-12 months. Updates should be done regularly.

Health of Capacitors: Capacitors should be replaced every 5-7 years as old caps lead to excessive noise under filtered and excessive subsonic noise termed noise and tripping.

Frequently Asked Questions (FAQ)

A VFD (Variable Frequency Drive) is used to control how fast an electric motor runs. It helps save energy, reduce wear on machines, and lets motors work only as hard as needed. You’ll find VFDs in fans, pumps, conveyors, and more.

In HVAC systems, VFDs control the speed of fans and pumps. They adjust how hard the system works based on room temperature. This saves energy, lowers noise, and helps keep the air comfortable.

The three main types of VFDs are:

VSI (Voltage Source Inverter) – Most common type.

CSI (Current Source Inverter) – Used in heavy-duty setups.

PWM (Pulse Width Modulation) – Makes motor speed smoother.

Each one works best for different motor needs.

In construction, VFDs control equipment like cranes, pumps, and fans. They help machines run safely and use less energy by adjusting motor speed as needed. This also makes equipment last longer.

Yes, VFDs are widely used today. They help save electricity and give better control over motors. From homes to big factories, VFDs are used almost everywhere to run machines smarter.

In a house, VFD means Variable Frequency Drive. It controls motor speed in things like well pumps, fans, or AC units. It saves energy and helps the system work more smoothly and quietly.

VFDs control the speed and torque of electric motors by adjusting the frequency and voltage of the power supplied to them. This improves energy efficiency and allows for better control over processes.

VFDs are more efficient than traditional motor starters because they allow for variable speed control, resulting in energy savings and better process control.

You can purchase VFDs from authorized distributors, online retailers, or directly from manufacturers’ websites.

Conclusion

VFDs are invaluable devices pertaining to modern motor control as they heighten energy control, process management, and prolong equipment lifespan.

No matter if you are involved with industrial automation, HVAC or agriculture, knowing how to select, install, and maintain these drives can be very beneficial for your projects.

To learn more or check purchase options, visit reputable suppliers or their authorized distributors. Acquiring VFDs is a move toward optimizing your processes and attaining improved operational efficacy.

Deep delve into our ABB VFDs or Allen Bradley VFDs!

8 thoughts on “Variable Frequency Drives (VFDs) Explained: Uses, Benefits & Selection Guide”